2024 New Technology Double Glass Automatic Sealing Robot

Model No.: HH-FJX-2230

Brand: HH

Place of Origin:China

Max Glass Size: 2200*3000 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In an industry driven by efficiency, consistency, and innovation, the 2024 New Technology Double Glass Automatic Sealing Robot is the next major leap in insulating glass manufacturing. Designed for modern production lines, this state-of-the-art equipment is redefining the standards of double glass unit sealing with unmatched precision and automation.

Whether you're upgrading your IGU production system or starting a new line, this Double Glass Automatic Sealing Robot is built to future-proof your business.

? What Is the 2024 New Technology Double Glass Automatic Sealing Robot?

The 2024 New Technology Double Glass Automatic Sealing Robot is an intelligent robotic sealing solution engineered specifically for double-glazed insulating glass units. It applies sealant with exceptional precision—ensuring perfect sealing edges every single time, regardless of glass size, shape, or complexity.

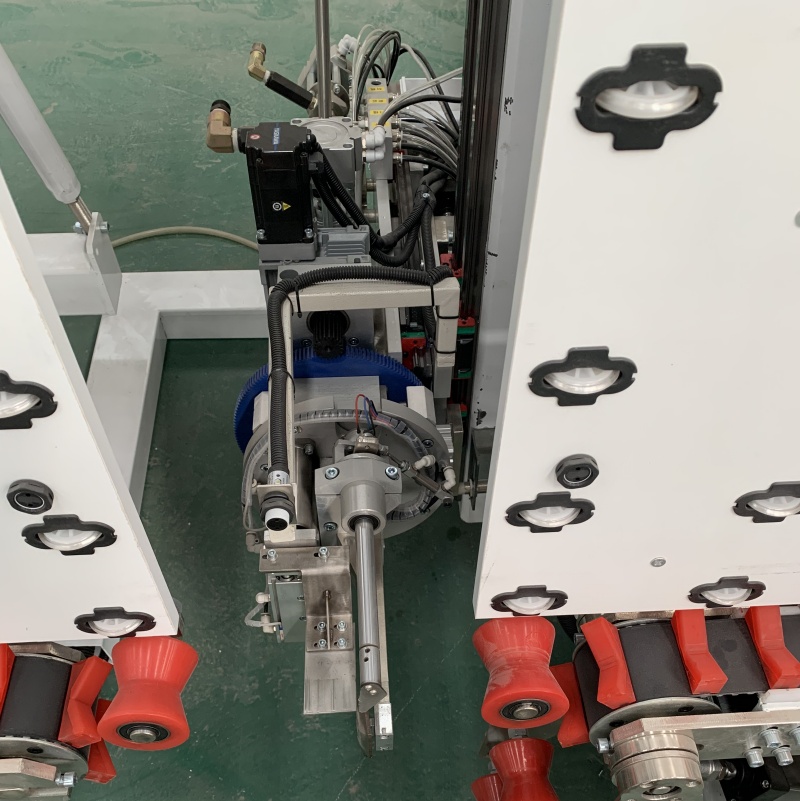

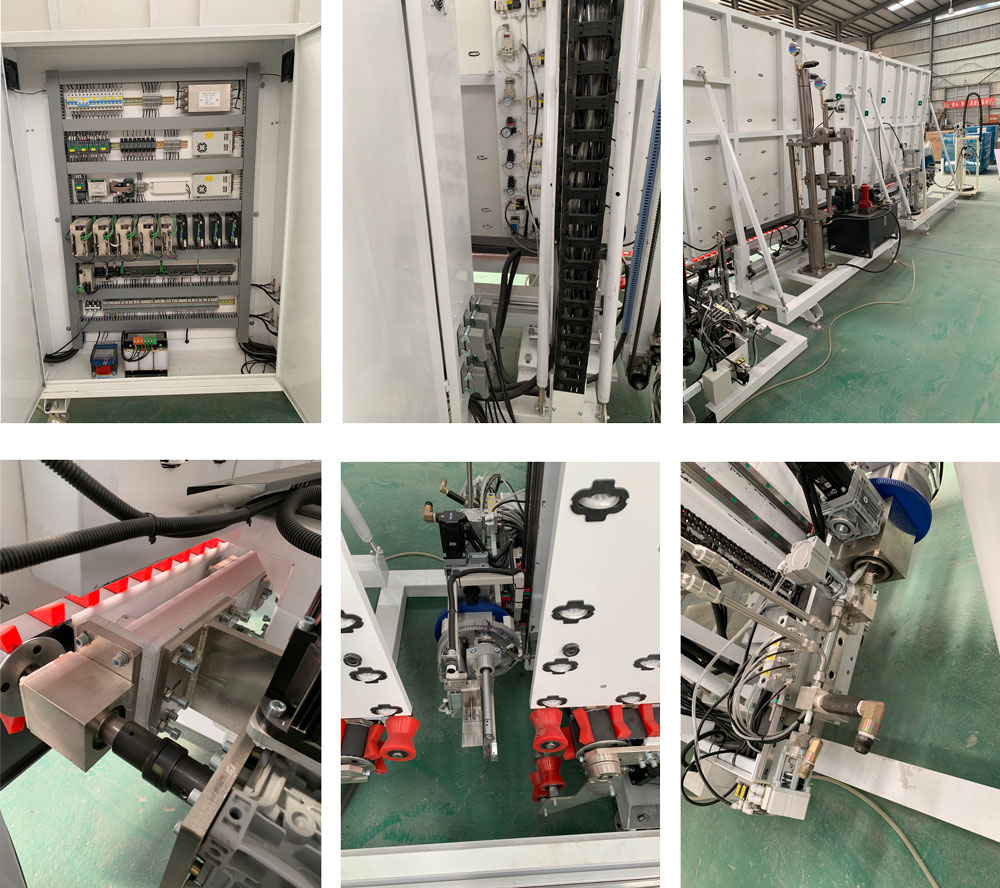

Built with the latest servo control systems, AI-driven pattern recognition, and adaptive flow technology, this robot transforms traditional labor-intensive sealing into a fast, flawless, and fully automated process.

? Key Features That Set It Apart

✅ AI-Powered Sealing Algorithm

Auto-detects IGU dimensions and adjusts sealant flow in real-time for flawless coverage.

✅ Dual-Arm Robotic System

Seals both horizontal and vertical edges simultaneously—boosting sealing speed by up to 40%.

✅ Industry 4.0 Compatibility

Connects seamlessly with your ERP or MES system, offering real-time performance tracking and diagnostics.

✅ Wide Sealant Compatibility

Supports structural silicone, polysulfide, and other energy-efficient IGU sealants.

✅ Ultra-Fine Control

±0.3 mm sealing accuracy, making it ideal for high-performance double glass units and low-E glass.

? “We were impressed with how adaptable the 2024 Double Glass Automatic Sealing Robot is. It even handles complex IGU shapes with zero flaws.”

— Raymond C., Head Engineer, Netherlands

? Technical Specifications

| Parameter | Value |

|---|---|

| Glass Size Range | 300mm – 3000mm (H) |

| Max Glass Thickness | Up to 60mm |

| Sealing Speed | 20–25 m/min |

| Control System | PLC + 15" Touchscreen HMI |

| Accuracy | ±0.3mm |

| Compatible Sealants | Silicone, Polysulfide, Polyurethane |

| Air Supply | 0.6–0.8MPa |

| Power Supply | 380V / 3 Phase / 50Hz |

? Why Upgrade to This 2024 Sealing Robot?

Choosing the 2024 New Technology Double Glass Automatic Sealing Robot isn’t just about adopting new machinery—it’s about investing in:

? Higher Production Throughput

Up to 600 units per shift with minimal operator intervention.? Intelligent Consistency

No missed spots, no human error. Every unit meets quality specs.? Material Efficiency

Smart flow control reduces sealant waste by 25% or more.? Reduced Labor Dependency

One operator can manage the entire sealing process with ease.

? Ideal Use Cases

This double glass sealing robot is perfectly suited for:

IGU manufacturers serving commercial and residential markets

Curtain wall and façade system producers

Energy-efficient and passive house window factories

Smart glass and photovoltaic IGU assembly lines

?️ “We installed this machine in February 2024, and by April, our output doubled. It’s quiet, fast, and incredibly easy to operate.”

— Daria P., Operations Manager, Poland

? Simulated Customer Feedback

⭐⭐⭐⭐⭐

“Honestly, I didn’t expect such a big jump in sealing speed and quality. We no longer rework any units due to sealant issues. This robot just nails it.”

— Ahmed M., IGU Production Manager, Egypt

⭐⭐⭐⭐

“Very intuitive controls and exceptional after-sales service. The installation team was knowledgeable and trained our staff in two days.”

— Jun W., Shenzhen, China

⭐⭐⭐⭐⭐

“The 2024 version feels like it’s from the future. Less waste, more speed, and quality we can count on. Highly recommended for any modern factory.”

— Maria L., Spain

? Business Benefits

✅ ROI in Less Than 12 Months

Labor savings, reduced defects, and faster turnaround = rapid return on investment.

✅ Boosted Customer Satisfaction

Consistent product quality means fewer complaints, more repeat orders.

✅ Scalable Growth

This machine adapts to increased production demands—no need for major future upgrades.

? Support, Installation & Warranty

We offer:

? Global shipping and logistics assistance

?️ On-site installation & staff training

? 1-year warranty + lifetime technical support

? Remote diagnostic system & software updates

Need a custom setup? We offer fully customized sealing robot configurations based on your IGU line.

Product advantages

(1)It can realize the continuity of gluing for insulating glass of various sizes, with high gluing efficiency and stable quality.

(2)The edges are glued and there are no bubbles in Guangzhou. The corners are composed of beautiful and elegant shapes and require manual trimming.

(3)The human-machine interface is simple and the operation interface is designed with simplified thinking. The glue pressure and various technical parameters are displayed on the screen in real time, and the observation and operation are simple and clear.

(4)Electrical components and cables are imported brands and are durable.

(5)Automatically complete the connection and gluing, the operation is simple and convenient.

(6)The entire machine parts are manufactured using CNC machining centers. The parts are highly standardized and can be connected to each other, which improves the convenience of maintenance and ensures the long-term stable use of the equipment.

(7)The equipment adopts a classic style with high precision, ensuring long-term stable use of the equipment.

(8)The servo control system adopts a world-renowned brand (Yaskawa, Japan), which has high stability, fast invasion speed and high glue dispensing accuracy.

Product parameters are as follows

Model | HH-FJX-2230 |

Power Supply | 380V 50Hz 15KW |

Air Pressure | 0.5~0.7Mpa |

Max. Glass Size | 2200x3000mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Working Speed | 0~50m/min |

Max. Dispensing Pressure | ≤35Mpa |

Overall Dimension | 11500x2000x3200mm |