Automatic Insulating Glass Argon Gas Filling Machine

Model No.: HH-CQX-2545

Brand: HH

Place of Origin:China

Max Glass Size: 2500*4500 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

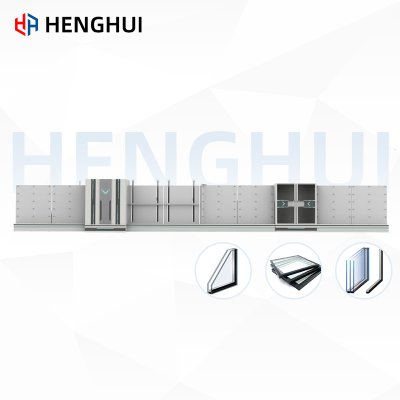

The Automatic Insulating Glass Argon Gas Filling Machine is a critical piece of equipment in the insulated glass (IG) manufacturing industry. Designed to precisely fill insulating glass units with argon gas, this machine improves thermal performance, energy efficiency, and sound insulation of IG products. As demand for high-quality, energy-saving windows grows, the Automatic Insulating Glass Argon Gas Filling Machine becomes indispensable for modern glass factories.

This article delves into the features, benefits, and applications of the Automatic Insulating Glass Argon Gas Filling Machine, helping manufacturers optimize production and quality.

What Is an Automatic Insulating Glass Argon Gas Filling Machine?

The Automatic Insulating Glass Argon Gas Filling Machine is an advanced automated system engineered to fill insulating glass units with argon gas efficiently and accurately. Argon gas, an inert and non-toxic gas, is injected between glass panes to enhance insulation by reducing heat transfer and preventing condensation.

This machine integrates automatic detection, argon gas injection, and sealing processes, minimizing gas leakage and ensuring consistent quality.

Key Features of Automatic Insulating Glass Argon Gas Filling Machine

High Filling Accuracy: Precise control ensures argon gas fills at optimal pressure and volume.

Automated Operation: Minimal manual intervention improves efficiency and reduces labor costs.

Leakage Detection: Built-in systems monitor and prevent argon gas leakage during and after filling.

Compatibility: Suitable for various insulating glass sizes and thicknesses.

User-Friendly Interface: Touchscreen control panels simplify operation and maintenance.

Energy Efficient: Designed to minimize gas waste and power consumption.

Benefits of Using an Automatic Insulating Glass Argon Gas Filling Machine

Improved Thermal Insulation: Argon-filled IG units reduce heat loss, enhancing building energy efficiency.

Consistent Product Quality: Automated filling ensures uniform argon distribution and reduces defects.

Higher Production Efficiency: Fast filling speeds and automation boost manufacturing throughput.

Cost Savings: Reduced argon gas consumption and labor costs lower overall production expenses.

Environmental Impact: Energy-efficient operation and inert argon gas contribute to greener manufacturing.

Applications of Automatic Insulating Glass Argon Gas Filling Machines

Window and Door Manufacturing: Ensures superior insulation in residential and commercial IG products.

Architectural Glass Production: Used in producing curtain walls and energy-saving glass facades.

Automotive Industry: Enhances thermal and acoustic performance of automotive insulated glass.

Specialty Glass Manufacturing: Suitable for IG units requiring high-performance gas filling.

How to Choose the Right Automatic Insulating Glass Argon Gas Filling Machine?

Consider your production capacity and glass unit sizes.

Evaluate machine accuracy, automation level, and after-sales support.

Check compatibility with your existing production line.

Prioritize machines with energy-saving features and reliable leakage detection.

Conclusion

The Automatic Insulating Glass Argon Gas Filling Machine is essential for modern insulating glass manufacturing, offering precise, efficient, and reliable argon gas filling. Investing in this technology boosts product quality, production efficiency, and sustainability, helping manufacturers stay competitive in the growing energy-efficient glass market.

Product advantages

(1)PLC control, touch screen human-machine interface, easy to operate.

(2)Can make double-layer, triple-layer, large and small glass, etc., automatically identify coated glass and LOW-E glass film.

(3)Imported glass suction cups and vacuum generators, better glass grabbing effect

(4)The protective plate is sprayed with plastic, with good performance and long service life

(5)The cleaning parts are made of stainless steel and resistor materials, and all electrical components are internationally renowned brands

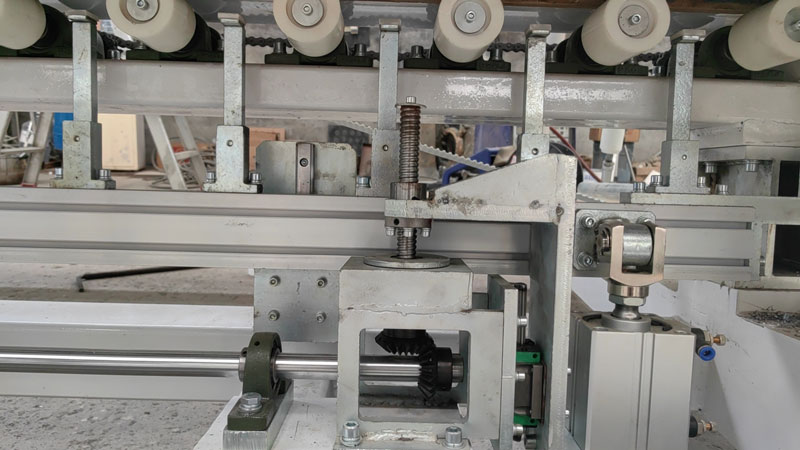

(6)The pressing part can be widened to 450mm for easy maintenance. The pressing part adopts an open door type for easy maintenance.

Product parameters are as follows

Model | HH-CQX-2545 |

Power Supply | 380V 50Hz 45KW |

Air Pressure | 0.6~0.8Mpa |

Max. Glass Size | 2500×4500mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Conveying Speed | 0~50m/min |

Cleaning Speed | 2~12m/min |

Overall Dimension | 31000×2000×3600mm |