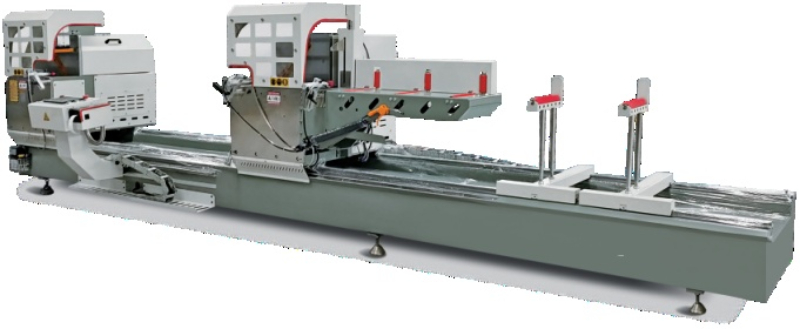

CNC Double-head Cutting Saw in 45 Angle

Model No.: LJZ-CNC-550×4200

Brand: HH

Place of Origin:China

Dimension Size: 6200×1750×1600mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

CNC Double-head Cutting Saw in 45 Angle: Precision Cutting for Modern Manufacturing

In the world of precision manufacturing, the CNC double-head cutting saw in 45 angle has become an indispensable tool. Whether you're working with aluminum profiles, PVC frames, or various industrial materials, this machine ensures superior accuracy and efficiency. The ability to achieve perfect 45-degree cuts is crucial for creating flawless joints, especially in industries such as window and door fabrication, automotive components, and architectural structures.

What is a CNC Double-head Cutting Saw in 45 Angle?

A CNC double-head cutting saw in 45 angle is a high-precision, computer-controlled machine designed to cut materials simultaneously from two ends. Both heads are fully programmable, allowing operators to achieve exact cuts at 45 degrees or other specified angles. This not only speeds up production but also significantly enhances the consistency of the finished products.

The design of the CNC double-head cutting saw in 45 angle prioritizes stability, accuracy, and ease of operation. With automated settings, adjustable cutting lengths, and intuitive control panels, it minimizes manual errors and maximizes throughput. Modern versions often include features like servo motor drive systems, touch-screen controls, and advanced cooling mechanisms to maintain blade integrity and ensure longer service life.

Key Features of a CNC Double-head Cutting Saw in 45 Angle

Choosing a CNC double-head cutting saw in 45 angle means investing in technology that boosts productivity and precision. Key features typically include:

Automatic Head Adjustment: Both cutting heads can adjust automatically to 45 degrees or customized angles as needed.

High-precision Blades: Carbide-tipped blades ensure clean and accurate cuts, even on thick or dense materials.

Robust Structure: Heavy-duty frames reduce vibration during cutting, enhancing overall accuracy.

Programmable Cutting Cycles: Operators can save cutting patterns for future use, optimizing workflow.

Advanced Safety Systems: Emergency stop functions, protective covers, and smart sensor technologies ensure safe operation.

These features make the CNC double-head cutting saw in 45 angle the preferred choice for factories seeking to streamline their cutting processes without compromising quality.

Applications of CNC Double-head Cutting Saw in 45 Angle

The versatility of the CNC double-head cutting saw in 45 angle makes it suitable for a wide range of industries:

Aluminum and PVC Window Frames: Creating precise corner joints with minimal material wastage.

Furniture Manufacturing: Achieving seamless 45-degree cuts for frames, cabinets, and decorative structures.

Architectural Installations: Cutting panels, trims, and structural elements with high precision.

Automotive Industry: Producing components that require strict dimensional tolerances.

Using a CNC double-head cutting saw in 45 angle helps manufacturers achieve uniformity across large production batches, ensuring each piece meets exact specifications.

Advantages of Using a CNC Double-head Cutting Saw in 45 Angle

Investing in a CNC double-head cutting saw in 45 angle offers numerous benefits:

Enhanced Productivity: Dual cutting heads reduce cycle time and allow simultaneous processing of multiple workpieces.

Consistent Quality: Computer-controlled operations eliminate human error, ensuring every cut meets tight tolerances.

Material Savings: Precise cuts reduce material wastage, lowering overall production costs.

Long-term Reliability: Sturdy build quality and intelligent systems contribute to longer machine life and reduced downtime.

Operator-Friendly: User interfaces are designed for ease of use, requiring minimal training for effective operation.

These advantages underline why a CNC double-head cutting saw in 45 angle is an essential asset in today’s competitive manufacturing environments.

How to Choose the Right CNC Double-head Cutting Saw in 45 Angle

When selecting a CNC double-head cutting saw in 45 angle, consider the following factors:

Material Compatibility: Ensure the saw is optimized for the materials you work with most frequently.

Cutting Range and Capacity: Choose a machine that can handle the sizes and thicknesses your projects demand.

Software and Control System: Advanced CNC systems offer better programming flexibility and production reporting.

Maintenance and Support: Reliable after-sales service ensures your investment continues to deliver value over time.

Careful evaluation will help you select a CNC double-head cutting saw in 45 angle that matches your specific production needs and business goals.

Conclusion

The CNC double-head cutting saw in 45 angle represents the future of precision cutting in manufacturing. By combining speed, accuracy, and reliability, it empowers businesses to deliver high-quality products while optimizing operational efficiency. Whether you are upgrading your facility or starting a new project, integrating a CNC double-head cutting saw in 45 angle will give you a powerful competitive advantage.