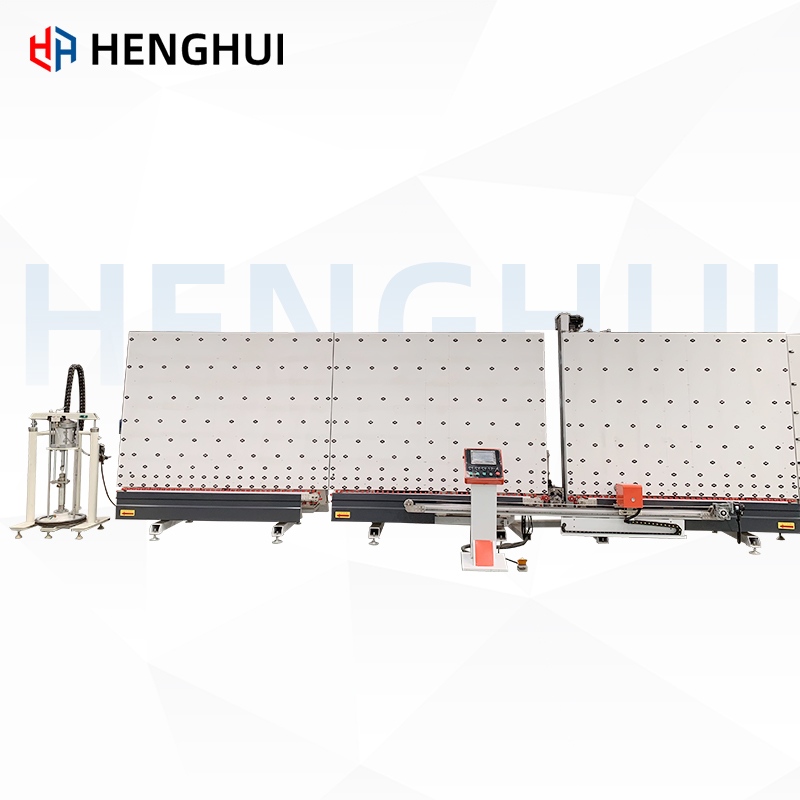

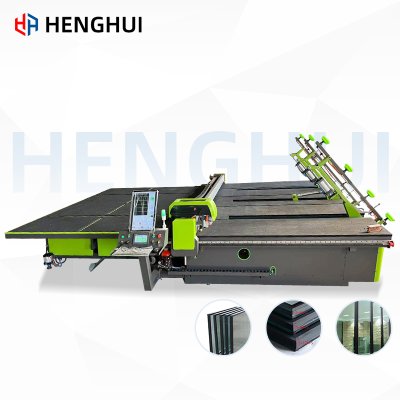

Insulating Glass Automatic Sealing Robot Machine

Model No.: HH-FJX-1825

Brand: HH

Place of Origin:China

Max Glass Size: 1800*2500 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In today's energy-conscious construction world, precision and speed in insulating glass production are no longer optional—they’re essential. That’s where the Insulating Glass Automatic Sealing Robot Machine comes in. Whether you're running a large-scale IGU production line or scaling up your workshop, this cutting-edge machine transforms how you seal insulating glass units—efficiently, consistently, and automatically.

? What Is an Insulating Glass Automatic Sealing Robot Machine?

The Insulating Glass Automatic Sealing Robot Machine is a high-tech, fully automated system designed to apply sealant evenly and accurately to double or triple-glazed insulating glass units. Powered by advanced robotic arms and intelligent control software, it replaces manual sealant application with unmatched precision and speed.

With vertical positioning, touch-free operation, and compatibility with a wide range of sealants (silicone, polysulfide, butyl), it’s a must-have for any IGU production line focused on quality and scalability.

✨ Key Features of the Insulating Glass Automatic Sealing Robot Machine

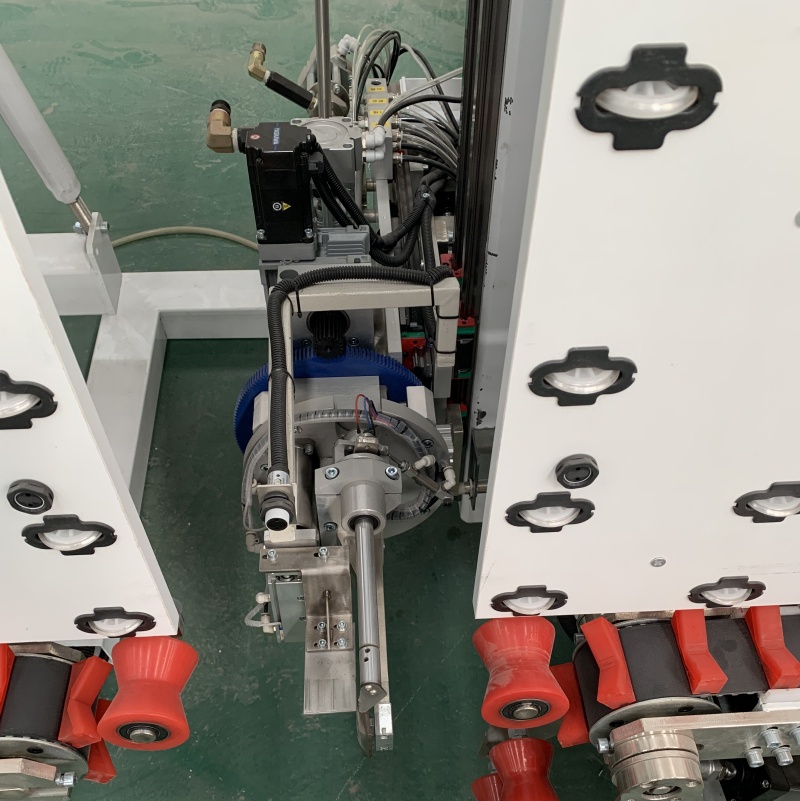

✅ Robotic Precision Sealing

The robotic system ensures exact sealant coverage on all edges—even for complex triple-glass IGUs—with an accuracy margin of ±0.5 mm.

✅ Seamless Integration

Easily integrates into your existing IGU production line. Works with spacer applicators, gas-filling units, and pressing machines.

✅ Dual-Axis Operation

Advanced motion control allows simultaneous sealing of vertical and horizontal edges—drastically reducing cycle time.

✅ Intelligent Touchscreen Interface

The user-friendly HMI system lets you control pressure, speed, sealant type, and more with just a few taps.

✅ Compatible with Multiple Sealants

Silicone, polysulfide, and other structural sealants can be dispensed accurately with programmable settings.

? Why Use an Insulating Glass Automatic Sealing Robot Machine?

The benefits go far beyond automation. This machine solves real production problems:

Eliminates human error in sealing

Saves 40–60% on labor costs

Boosts production capacity by up to 50%

Ensures consistent bonding strength across all units

Reduces material waste through accurate dispensing

? “After using the Insulating Glass Automatic Sealing Robot Machine for just one month, our team was amazed at the sealing uniformity—and how many hours it saved us daily.”

— Felix R., Plant Supervisor, Austria

? Technical Specifications

| Specification | Detail |

|---|---|

| Glass Size Range | 300mm – 2500mm height |

| Glass Thickness | 3mm – 60mm |

| Working Speed | Up to 20m/min |

| Accuracy | ±0.5mm |

| Compatible Sealants | Silicone, Polysulfide, Butyl |

| Air Supply | 0.6-0.8MPa |

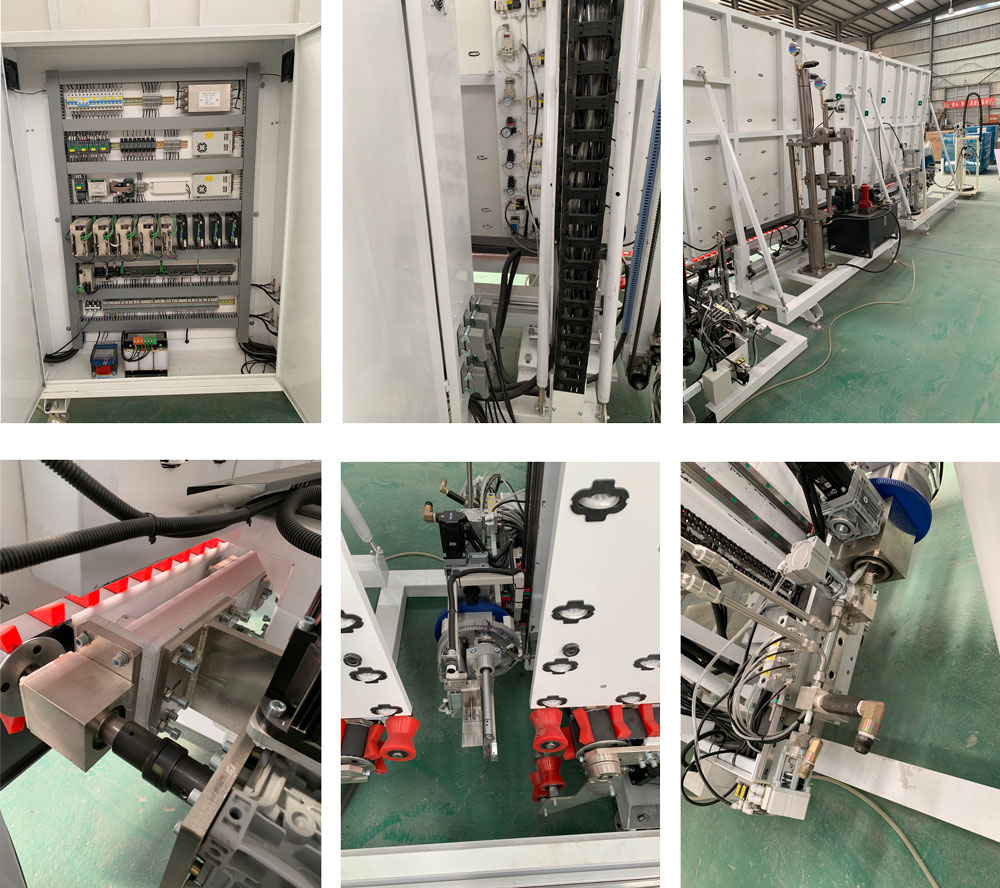

| Control System | PLC + Touchscreen HMI |

| Power Supply | 380V / 3 Phase |

Need to seal oversized or specialty IGUs? Customized solutions available.

? Ideal Applications

The Insulating Glass Automatic Sealing Robot Machine is widely used in:

Commercial IGU production lines

Passive house and energy-efficient window manufacturing

Curtain wall and high-rise façade systems

Architectural, residential, and smart glass projects

Whether you're producing 100 or 1000 units a day, this machine scales with your business.

? Real-World Customer Reviews

⭐⭐⭐⭐⭐

“We used to rely on manual sealant work, but once we installed the Insulating Glass Automatic Sealing Robot Machine, everything changed. Our defect rate dropped by over 70%, and customer satisfaction skyrocketed.”

— Hassan A., UAE

⭐⭐⭐⭐

“The initial investment pays off fast. With one operator managing the machine, we produce 30% more IGUs daily. Seamless software, very easy to learn.”

— Chen W., China

⭐⭐⭐⭐⭐

“It applies the perfect amount of sealant every time—no more messy edges or rework. Excellent machine for professional-grade IGUs.”

— Laura G., Spain

?️ Installation & After-Sales Service

We provide on-site installation, operator training, and lifetime technical support. Our engineering team is ready to customize your machine to fit your plant’s layout and specific production requirements.

Warranty: 12 months

Spare parts: Always in stock

Service response: Within 24 hours (worldwide)

? Why This Machine Is a Smart Investment

? Payback in Less Than a Year

Due to labor cost reduction and increased production efficiency.

? Environmentally Friendly

Minimized sealant waste = lower environmental impact and lower cost.

? Consistent Product Quality

No air bubbles, no sealant gaps—only professional-grade IGUs.

Product advantages

(1)9 axis linkage, suitable for mass production of glass.

(2)Man-machine interface, simplified design, more convenient operation.

(3)The third section can store glass to improve production efficiency.

(4)The glass edge is full without air line, and the corner is flat without corner repair.

(5)Servo control system adopts world famous brand, stable performance.

(6)Synchronous belt transmission ensures smooth glass transmission and accurate positioning.

(7)Unique V transmission mode can reduce the adhesive phenomenon of conveyor belt and ensure the glass edge clean.

(8)High standard parts and components ensure long-term and stable use of equipment

Product parameters are as follows

Model | HH-FJX-1800x2500 |

Power Supply | 380V 50Hz 13KW |

Air Pressure | 0.5~0.7Mpa |

Max. Glass Size | 1800x2500mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Working Speed | 0~50m/min |

Max. Dispensing Pressure | ≤35Mpa |

Overall Dimension | 9500x2000x2800mm |