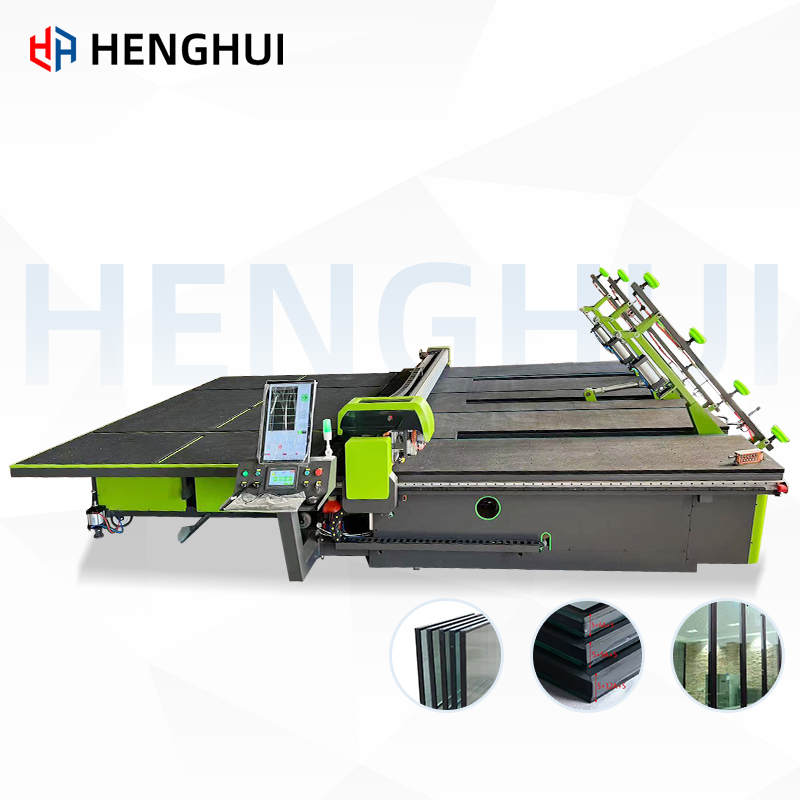

High Efficiency Automatic Cutting Table Glass Cutting Machine

Model No.: HH-BQJ-3628

Brand: HH

Place of Origin:China

Capacity: 1000m²/day

Payment Type:L/C,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In the fast-paced world of glass fabrication, precision and efficiency are non-negotiable. Enter the high efficiency automatic cutting table glass cutting machine, a game-changing innovation that combines advanced automation with unmatched accuracy to meet the demands of modern glass processing industries.

Whether you’re in architectural glass, automotive glazing, or decorative glass manufacturing, this cutting-edge equipment is designed to elevate your production capabilities while reducing waste and labor costs.

What Is a High Efficiency Automatic Cutting Table Glass Cutting Machine?

A high efficiency automatic cutting table glass cutting machine is an advanced piece of machinery engineered to automate the entire glass cutting process. It integrates CNC technology, precise servo motors, and intelligent software to deliver fast, accurate cuts on various glass thicknesses and types.

The cutting table provides a stable, flat surface, while automated loading and cutting systems ensure continuous, uninterrupted operation, boosting overall efficiency.

Key Features and Benefits

1. Exceptional Cutting Precision

With state-of-the-art laser guidance and servo motor control, the high efficiency automatic cutting table glass cutting machine guarantees precision cutting to micron-level accuracy. This minimizes material waste and enhances product quality.

2. Increased Productivity

Automation dramatically speeds up the cutting process. Operators can program complex cutting patterns that the machine executes flawlessly, often completing jobs in a fraction of the time manual cutting would require.

3. Versatility Across Glass Types

From tempered and laminated glass to ultra-clear and tinted variants, this machine adapts seamlessly. It supports multiple thickness ranges and customized cutting paths tailored to specific project needs.

4. User-Friendly Interface

Modern machines feature intuitive touchscreens and software that allow operators—even those with minimal experience—to set parameters quickly and monitor production in real-time.

5. Enhanced Safety and Reduced Labor

By automating repetitive, dangerous tasks, the high efficiency automatic cutting table glass cutting machine lowers workplace injury risks and reduces the need for manual labor, which translates into cost savings.

Applications of High Efficiency Automatic Cutting Table Glass Cutting Machine

Architectural Glass Production: Precise cuts for windows, facades, and partitions.

Automotive Glass Manufacturing: Fast and accurate shaping of windshields and mirrors.

Furniture and Decorative Glass: Custom designs with intricate patterns.

Solar Panel Glass Cutting: Consistent quality for renewable energy components.

Technical Specifications (Typical Model Example)

| Specification | Details |

|---|---|

| Cutting Table Size | 3000mm x 2000mm |

| Glass Thickness Range | 2mm – 19mm |

| Cutting Speed | Up to 15 m/min |

| Positioning Accuracy | ±0.1 mm |

| Control System | CNC with touch screen |

| Power Supply | 380V / 50Hz |

| Automation Level | Fully automatic with loading |

User Reviews: Real Feedback from Glass Industry Professionals

@GlassMasterTom

“The high efficiency automatic cutting table glass cutting machine transformed our workshop. We’ve cut production time by 40%, and the precision is simply unmatched.”

@EcoGlassSolutions

“Reducing material waste was our top priority. This machine’s accuracy helped us save thousands of dollars per month.”

@InnovativeGlassCo

“Even operators new to the technology find the interface easy to use. It’s a solid investment for any growing glass business.”

How to Choose the Right High Efficiency Automatic Cutting Table Glass Cutting Machine?

Assess Your Production Volume: Choose a model with appropriate cutting speeds and table size.

Check Glass Compatibility: Ensure the machine supports the thickness and types of glass you use.

Evaluate Automation Features: Consider machines with loading/unloading automation to maximize efficiency.

Review After-Sales Support: Reliable technical support and training are vital for smooth operation.

Budget and ROI: Balance upfront cost with long-term savings from labor reduction and waste minimization.

Frequently Asked Questions

Q: Can the machine handle curved or irregular shapes?

A: Yes, advanced CNC programming allows for intricate cuts, including curves and custom shapes.

Q: What maintenance does the machine require?

A: Routine cleaning, lubrication of moving parts, and periodic software updates keep the machine running optimally.

Q: Is the machine compatible with industry 4.0 standards?

A: Many models offer IoT integration for remote monitoring and data analytics.

Conclusion: Boost Your Glass Cutting Operations Today

Investing in a high efficiency automatic cutting table glass cutting machine means embracing the future of glass fabrication. From exceptional precision to increased throughput and improved workplace safety, this machine is designed to meet and exceed the evolving demands of the glass industry.

2. Product advantages

(1) The machine combines the functions of upper chip handling, conveying, cutting, and splitting, achieving a high level of integration.

(2) Featuring the latest generation control system, it achieves fast cutting speeds and high cutting quality. It includes automatic laser positioning, graphic scanning, automatic labeling, and other advanced functions.High efficiency automatic glass cutting machine

(3) It utilizes a high-hardness knife wheel imported from Germany for precise cutting, with a protective device on the knife head to prevent collisions.

(4) The internal air pump and air source filter ensure that the cutting assembly performs stable and efficient high-speed cutting, significantly reducing the failure rate.

3. Product parameters are as follows

Model | HH-BQJ-3628 |

Voltage Power | 380V 50Hz 6KW |

Max.Glass Upper Piece Size | 3660*2800mm |

Glass Upper Piece Thickness | 3~19mm |

Cutting Speed | 0~190m/min |

Labeling Function | Yes(Optional) |

Delivery function | Yes(Optional) |

Qty Upper Piece Arm | 3 piece |

Overall Dimension | 4200*3500*820mm |