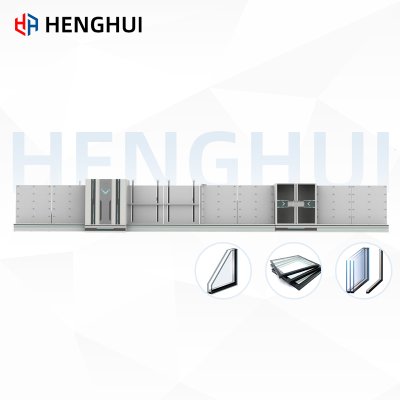

End-milling Machine for Aluminum Door

Model No.: LXD-250B

Brand: HH

Place of Origin:China

Dimension Size: 2700×1000×1750mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In the modern era of construction and architecture, precision and efficiency are everything—especially when working with aluminum door systems. Investing in the right end-milling machine for aluminum door manufacturing can dramatically improve your productivity, finish quality, and overall profitability. Whether you're a large-scale fabricator or a specialized workshop, the end-milling machine for aluminum door production is a cornerstone tool that determines your output speed and professional finish.

What Is an End-Milling Machine for Aluminum Door Processing?

An end-milling machine for aluminum door manufacturing is a precision tool engineered to mill, notch, or groove the ends of aluminum profiles. This machine is specifically designed to handle the hardness and properties of aluminum alloys used in door and window systems. By delivering clean, accurate cuts, it ensures perfect profile connections—vital for airtight seals and flawless assemblies.

Why Choose a Professional End-Milling Machine for Aluminum Door Production?

✅ Precision Engineering

A premium end-milling machine for aluminum door systems allows you to execute high-accuracy cuts and notches for complex profile joints. These machines are built to handle diverse milling angles, ensuring flexibility in fabrication. The precision directly impacts the structural integrity and visual appeal of your finished aluminum doors.

✅ High-Speed Operation

Speed matters. Top-quality end-milling machines for aluminum door production are equipped with powerful motors and optimized milling heads, enabling them to process dozens of profiles quickly—without sacrificing quality. This means higher throughput, faster deliveries, and increased profits.

✅ Minimal Waste, Maximum Output

Thanks to smart clamping systems, auto-positioning stops, and digital angle adjustment, modern end-milling machines for aluminum door applications minimize material loss. Reduced waste means more savings on raw materials and a stronger bottom line.

✅ Durability & Long Lifespan

A robust frame, precision linear guides, and wear-resistant components ensure that your end-milling machine for aluminum door fabrication lasts for years. Minimal downtime means uninterrupted production and fewer maintenance headaches.

Key Features to Look for in an End-Milling Machine for Aluminum Door Production

When selecting an end-milling machine for aluminum door tasks, ensure it includes:

Adjustable Spindle Speed – To handle different aluminum grades and profile complexities.

Multi-Angle Milling Capability – For enhanced design flexibility and custom door profiles.

Heavy-Duty Clamping System – To maintain stability and accuracy during operations.

Noise & Vibration Reduction Design – For a safer and more comfortable working environment.

CNC or PLC Interface (Optional) – For precision automation and repeatability.

Applications of End-Milling Machines for Aluminum Door Fabrication

The end-milling machine for aluminum door projects is essential for:

Notching and grooving aluminum door frames

Corner joining preparations

Custom profile milling

Hinge and lock recessing

Window & curtain wall systems

Whether you're producing sliding doors, casement systems, or high-performance thermal break profiles, this machine enhances your workflow significantly.

Who Should Invest in an End-Milling Machine for Aluminum Door Systems?

This machine is ideal for:

Aluminum door manufacturers

Window and curtain wall fabricators

Architectural metal workshops

OEM door system suppliers

Construction contractors with in-house fabrication needs

If your business values precision, productivity, and professional-grade results, the end-milling machine for aluminum door tasks is a must-have asset.

Boost Your Business with the Right End-Milling Machine for Aluminum Door Production

Investing in the right end-milling machine for aluminum door manufacturing isn’t just about equipment—it’s about unlocking a new level of efficiency and craftsmanship. The right machine reduces labor costs, improves finish quality, and helps you take on complex projects with ease.

Imagine being able to deliver custom aluminum door solutions faster, with perfect alignment, tighter seals, and zero rework. That’s the kind of competitive edge that only a high-performance end-milling machine for aluminum door production can offer.

Why Now Is the Time to Upgrade

With rising demand for lightweight, energy-efficient aluminum doors in commercial and residential projects, the market is growing fast. By upgrading your fabrication line with a powerful, reliable end-milling machine for aluminum door work, you’re not just keeping pace—you’re pulling ahead.

Final Thoughts

Whether you're scaling production or upgrading your current facility, a top-tier end-milling machine for aluminum door applications delivers unmatched results. It’s the secret weapon behind clean cuts, perfect fits, and premium-quality aluminum doors.

Don’t settle for second-best. Choose precision. Choose performance. Choose the best end-milling machine for aluminum door fabrication today.