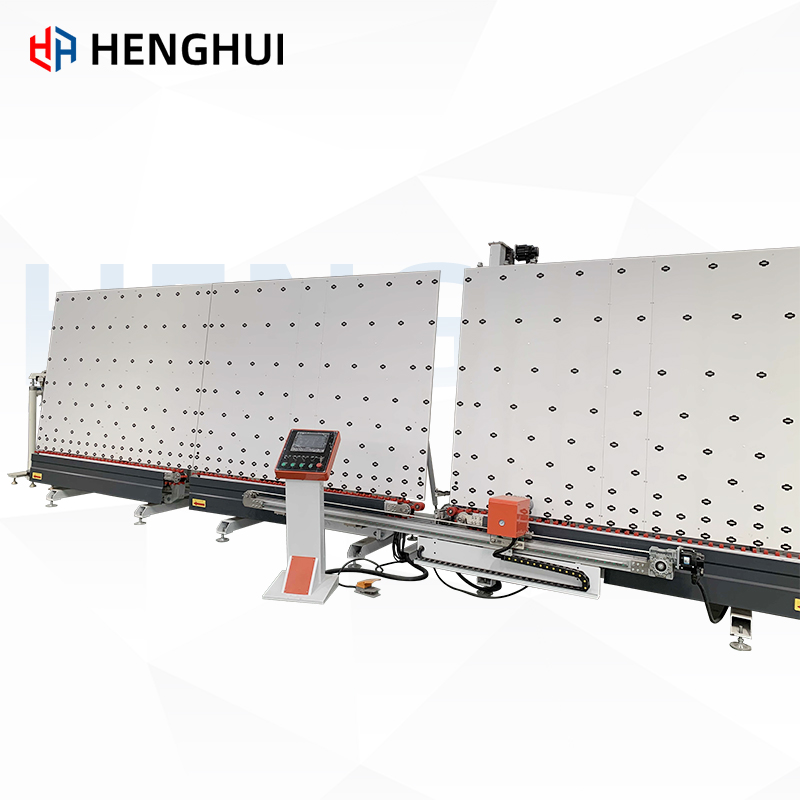

Vertical Insulating Triple-glass Sealant Coating Machine

Model No.: HH-FJX-2540

Brand: HH

Place of Origin:China

Max Glass Size: 2500*4000 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In the fast-evolving world of energy-efficient buildings, the demand for vertical insulating triple-glass sealant coating machines has skyrocketed. Architects, contractors, and glass processors are seeking smarter, faster, and more precise ways to manufacture triple-glass insulated glazing units (IGUs) — and this machine is the answer.

Whether you're upgrading your factory's output or entering the insulated glass industry, understanding how the vertical insulating triple-glass sealant coating machine can enhance your workflow is the key to staying competitive.

? What Is a Vertical Insulating Triple-glass Sealant Coating Machine?

This highly automated machine is designed for the precise application of sealant on triple-glass IGUs, ensuring uniform coating and long-lasting bonding. Unlike conventional horizontal systems, the vertical configuration saves space and allows better visibility during operation.

It works seamlessly with warm edge spacers, structural silicone, and polyurethane sealants — making it ideal for both standard and high-performance triple-glass systems.

✨ Key Features & Benefits

✅ Vertical Structure for Streamlined Workflow

The vertical design minimizes the machine's footprint, increases safety, and allows operators to monitor the sealing process in real time.

✅ Accurate Sealant Coating for Triple IGUs

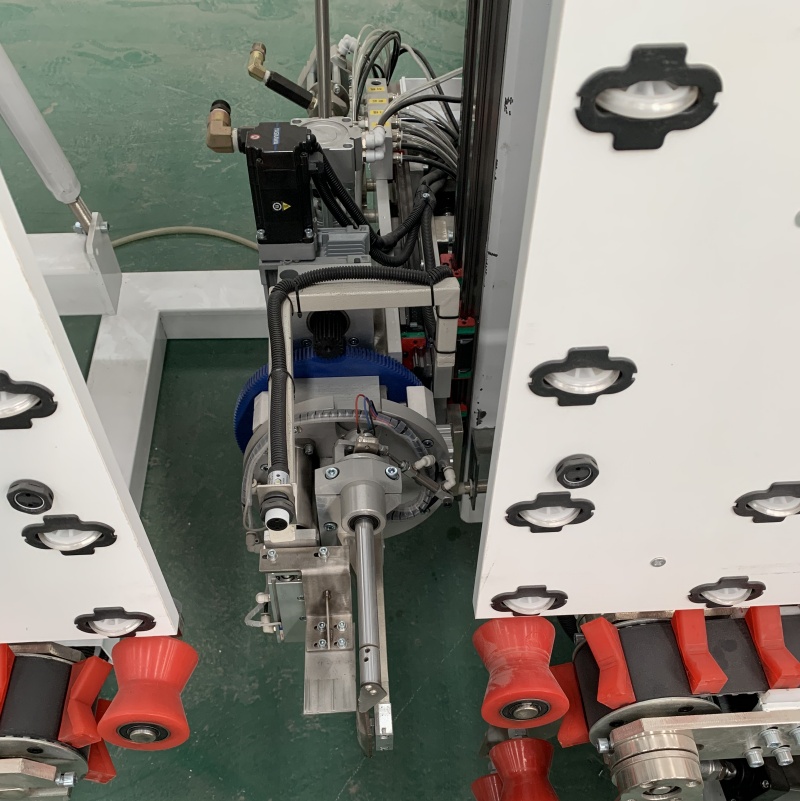

Equipped with multi-axis control and intelligent sensors, this machine applies sealants with extreme precision — even between three glass panes.

✅ High-speed, Automated Operation

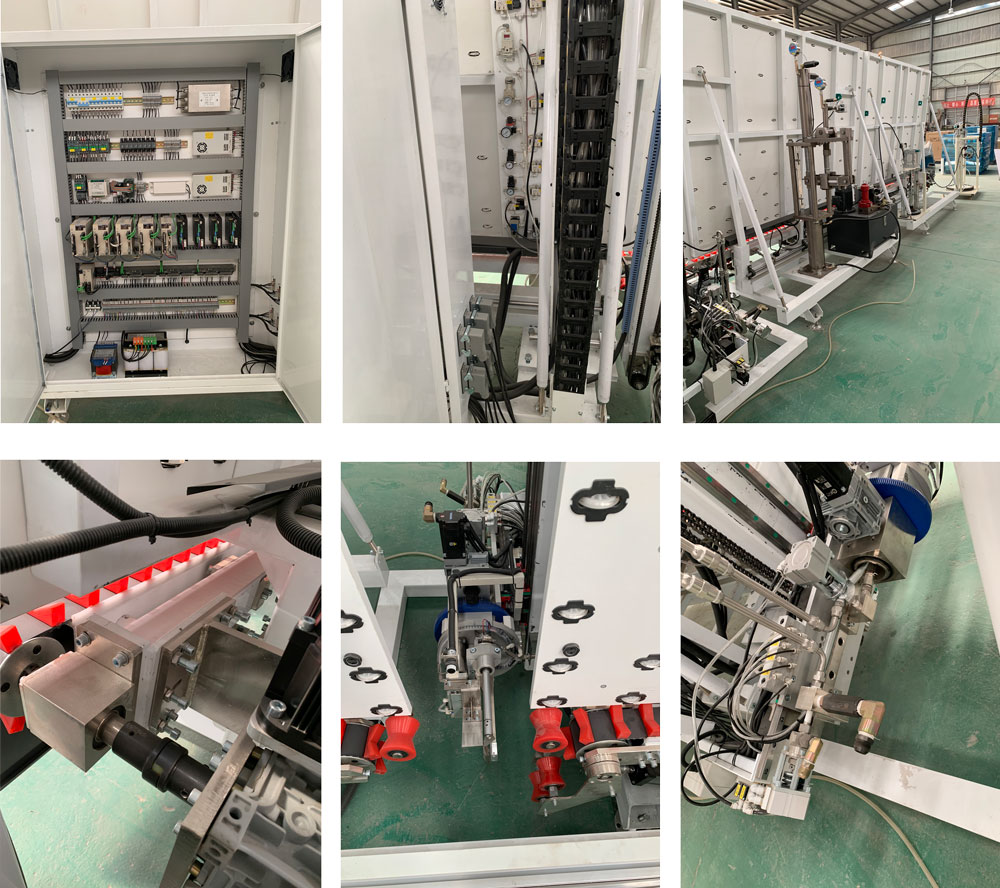

A programmable logic controller (PLC) and servo-driven system enable faster production speeds without compromising accuracy.

✅ Compatible with Multiple Sealants

Whether you're using silicone, polysulfide, or butyl, this system handles them all with consistent performance.

✅ Touchscreen HMI for Easy Operation

Operators can manage production parameters, speed, and sealant quantity via an intuitive user interface — reducing the learning curve.

? Technical Specifications (Sample)

| Parameter | Details |

|---|---|

| Glass Thickness | 3mm – 60mm |

| Glass Height | Max 2500mm |

| Speed | Up to 20m/min |

| Sealant Types | Silicone, Polysulfide, Butyl |

| Power Supply | 380V, 3 Phase |

| Control System | PLC + Touchscreen HMI |

| Coating Precision | ±0.5mm |

| Air Pressure | 0.6-0.8MPa |

Need a customized machine for oversized glass or integrated drying systems? We offer full customization based on your plant needs.

? Ideal Applications

The vertical insulating triple-glass sealant coating machine is perfect for:

Triple-pane insulated windows and doors

Passive house-certified IGUs

Curtain walls and structural glazing

High-rise, commercial, or residential façade systems

? “After switching to the vertical insulating triple-glass sealant coating machine, our output efficiency increased by 35%. And the coating precision is just amazing!”

— Michael Zheng, IGU Manufacturer, Germany

? Why This Machine Stands Out?

? Boosts Output with Consistency

With automation and intelligent control, production scales without human error.

? Reduces Labor Costs

One operator can manage the process, while the machine handles the sealant application seamlessly.

?️ Long-Term Durability

The machine's construction is designed for 24/7 operation in industrial environments with minimal downtime.

? Environmentally Friendly

Accurate sealant application means less waste — better for your budget and the planet.

?♂️ Frequently Asked Questions

Q: Can this machine work with Low-E glass units?

A: Yes. It's fully compatible with Low-E, laminated, and even tempered triple-glass panels.

Q: How long does it take to train a new operator?

A: With our intuitive HMI and training manual, most operators can be trained within 1–2 days.

Q: Is there a warranty and after-sales service?

A: Absolutely. We offer a 12-month warranty, with lifetime technical support and on-site installation guidance.

? Customer Reviews

⭐⭐⭐⭐⭐

“We’ve tried both horizontal and vertical systems. This vertical insulating triple-glass sealant coating machine not only saved us floor space but also improved bonding consistency. Highly recommend for anyone scaling production.”

— Giovanni R., Italy

⭐⭐⭐⭐

“Sealant precision is top-notch, and support from the manufacturer was prompt during setup. We use it for all our triple-glass curtain walls now.”

— Qamar A., UAE

⭐⭐⭐⭐⭐

“The machine's automation has helped us reduce manual errors and save on sealant material. It paid for itself within the first year.”

— Andrew L., Canada

? Ready to Upgrade Your IGU Production?

If you're producing triple-pane units, don't let manual sealant errors or low output hold you back. The vertical insulating triple-glass sealant coating machine is the intelligent choice for any factory aiming to boost efficiency, consistency, and profitability.

? Contact us today for a free consultation or demo

? Get a quote tailored to your production scale

? Bulk orders welcome with flexible delivery options

? Let’s build better, smarter, and greener — together.

Product advantages

(1) Achieves seamless sealing of rectangular insulating glass of various sizes, ensuring high efficiency and stable quality.

(2) Offers two independent glue supply systems, with optional switch between two types of sealants.

(3) Enables pre-storage of glass in the third section for continuous equipment operation and improved production efficiency.

(4) Ensures full side coating without bubbles and seamless corners without manual trimming.

(5) Features a stable performance Yaskawa motion control system and servo control system, renowned globally.

(6) Employs an accurate synchronous belt transmission system for smooth, contamination-free glass handling.

(7) Includes dual sealant supply systems for quick switching and one-touch operation.

(8) Designed for triple glazing applications, accommodating diverse production needs.

Product parameters are as follows

Model | HH-FJX-2540 |

Power Supply | 380V 50Hz 13KW |

Air Pressure | 0.5~0.7Mpa |

Max. Glass Size | 2500×4000mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Working Speed | 0~50m/min |

Max. Dispensing Pressure | ≤35Mpa |

Overall Dimension | 12000×2000×3550mm |