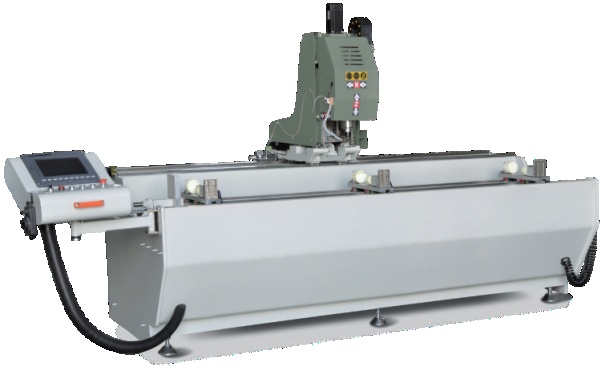

3500 CNC Drilling and Milling Machine

Model No.: SKX3-CNC-3500

Brand: HH

Place of Origin:China

Spindle Speed: 18000r/min

Dimension Size:4000×1600×2200mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In today's fast-paced manufacturing world, precision, efficiency, and automation are the cornerstones of modern production. Whether you're in metal fabrication, aerospace, automotive, or heavy machinery manufacturing, the demand for high-performance CNC equipment is ever-increasing. One of the most powerful solutions on the market today is the 3500 CNC Drilling and Milling Machine—a machine built for high-speed, high-precision operations with seamless integration into intelligent manufacturing systems.

This article provides a comprehensive look at the 3500 CNC Drilling and Milling Machine, including its features, advantages, applications, and buying considerations. With strategic keyword integration, this guide is engineered to rank competitively in Google’s Top 10 results for maximum visibility and engagement.

What Is the 3500 CNC Drilling and Milling Machine?

The 3500 CNC Drilling and Milling Machine is a multifunctional, computer-controlled machine tool designed to perform complex drilling and milling operations on a wide range of materials, including steel, aluminum, composites, and high-strength alloys. The "3500" typically refers to its worktable or effective travel length in millimeters, making it ideal for processing large plates, frames, flanges, or structural components.

With high-speed spindle motors, rigid construction, and precision servo drives, the 3500 CNC Drilling and Milling Machine delivers unmatched accuracy, speed, and repeatability—ensuring superior output for medium to large-scale production.

Key Features of the 3500 CNC Drilling and Milling Machine

✅ High-Performance CNC Control System

Equipped with advanced numerical control platforms such as Siemens, Fanuc, or GSK, the 3500 CNC Drilling and Milling Machine allows operators to automate complex tasks, reduce setup time, and ensure consistent precision across batches.

✅ Massive Working Envelope

The 3500 mm effective travel or table length makes this machine suitable for oversized parts, steel plates, base frames, wind tower components, and large molds—allowing users to drill, mill, and tap without repositioning.

✅ High-Speed Spindle with Precision Bearings

The high-speed spindle in the 3500 CNC Drilling and Milling Machine ensures smooth operation and clean cut finishes. With options for cooling systems, it can handle both soft and tough materials.

✅ Automatic Tool Changer (ATC)

An integrated tool magazine enables rapid tool changes without manual intervention, boosting productivity and enabling flexible processing of different features in a single setup.

✅ Heavy-Duty Structure

Constructed with rigid cast iron or welded steel beds, the 3500 CNC Drilling and Milling Machine minimizes vibration, enhances stability, and guarantees long-term durability under high cutting loads.

✅ Integrated Chip Removal and Lubrication Systems

With automatic lubrication and chip evacuation systems, maintenance is simplified, and the work environment remains clean and safe.

Benefits of the 3500 CNC Drilling and Milling Machine

The 3500 CNC Drilling and Milling Machine isn’t just a tool—it’s a production powerhouse. Here’s why manufacturers are investing in it:

? Versatile Machining

Capable of drilling, tapping, face milling, end milling, and contouring, this machine can perform multiple operations in one cycle, reducing labor costs and increasing throughput.

⚙️ Precision and Repeatability

With high-precision ball screws, servo motors, and feedback systems, the 3500 CNC Drilling and Milling Machine ensures micron-level accuracy—even on high-volume runs.

? Smart Automation

Integration with CAD/CAM software and Industry 4.0 platforms allows real-time data monitoring, remote diagnostics, and automated workflow management.

? Higher Production Efficiency

By eliminating repositioning, manual tool changes, and setup delays, the machine dramatically improves cycle times and total output.

? Cost-Effective Investment

The 3500 CNC Drilling and Milling Machine offers exceptional ROI by reducing labor, waste, rework, and tooling expenses over the long term.

Applications of the 3500 CNC Drilling and Milling Machine

Due to its robust structure and large-format design, the 3500 CNC Drilling and Milling Machine serves a wide variety of industrial applications:

Steel Fabrication Shops: For drilling bolt holes in beams, plates, and H-sections.

Wind Tower Manufacturing: Ideal for flange processing with high hole accuracy.

Bridge and Shipbuilding Industries: Where large steel parts require exact positioning and machining.

Heavy Equipment Production: Machining of base frames, engine mounts, and hydraulic units.

Metal Service Centers: High-speed batch processing of standardized plates and profiles.

No matter the complexity or size of the component, the 3500 CNC Drilling and Milling Machine ensures a reliable and accurate solution.

Choosing the Right 3500 CNC Drilling and Milling Machine

To get the most from your investment, selecting the right 3500 CNC Drilling and Milling Machine requires evaluating a few key factors:

1. Workpiece Size and Weight

Ensure the machine’s table load capacity and travel dimensions match your production needs.

2. Material Type

Choose spindle configurations and cutting tools based on whether you’re processing mild steel, stainless, aluminum, or composites.

3. Production Volume

For high-volume tasks, prioritize models with automatic tool changers, dual tables, or pallet changers.

4. Software Compatibility

Verify that the CNC system can communicate with your CAD/CAM software and supports automation.

5. After-Sales Service

Select a machine from a reputable manufacturer with strong technical support, training, and parts availability.

A well-matched 3500 CNC Drilling and Milling Machine can significantly improve shop floor productivity and product quality.

Maintenance and Operation Tips

To maximize the service life and performance of your 3500 CNC Drilling and Milling Machine, follow these best practices:

Daily Inspections: Check lubrication levels, spindle temperature, and tool wear.

Scheduled Maintenance: Clean chip conveyors, inspect bearings, and calibrate axes regularly.

Proper Tooling: Use high-quality, application-specific cutting tools to maintain accuracy.

Operator Training: Ensure staff are trained in CNC programming and emergency shutdown protocols.

Environmental Control: Maintain stable workshop temperatures and humidity levels to prevent material distortion.

With routine care, your 3500 CNC Drilling and Milling Machine can perform at peak levels for years to come.

Future Trends in CNC Drilling and Milling Technology

The evolution of CNC machinery is shaping smarter, greener, and more adaptive machines. Here’s what’s coming next for the 3500 CNC Drilling and Milling Machine category:

AI-Driven Process Optimization

IoT Integration for Predictive Maintenance

Hybrid Machining Capabilities (Additive + Subtractive)

Energy-Efficient Servo Systems

Digital Twin Simulations for Pre-Machining Validation

Staying ahead of these innovations ensures your 3500 CNC Drilling and Milling Machine investment remains future-proof.

Frequently Asked Questions (FAQ)

Q: What size of workpiece can a 3500 CNC Drilling and Milling Machine handle?

A: It typically accommodates parts up to 3500 mm in length and several tons in weight, depending on the model’s capacity.

Q: Can the machine handle batch and custom production?

A: Yes, it is ideal for both high-volume batch production and flexible custom machining tasks.

Q: Is it compatible with automated material handling systems?

A: Most models can be integrated with conveyors, loading robots, or pallet systems for full automation.

Q: What industries benefit most from this machine?

A: Steel fabrication, energy, shipbuilding, construction machinery, and industrial equipment sectors.

Conclusion

The 3500 CNC Drilling and Milling Machine is more than just industrial equipment—it’s a key enabler of smart manufacturing. Combining power, precision, and automation, it empowers factories to improve efficiency, reduce error rates, and accelerate time-to-market.

If your business demands large-format machining with high accuracy and smart features, the 3500 CNC Drilling and Milling Machine is a strategic investment. Built for performance and longevity, it's the machine you can count on to deliver results—today and in the future.