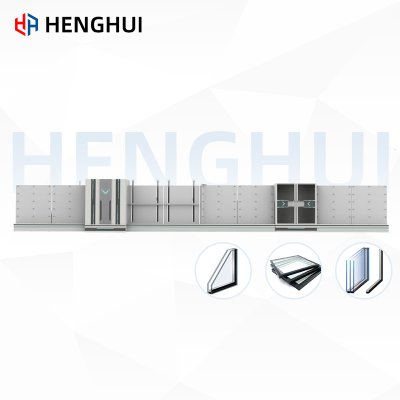

CNC Aluminum Profile Drilling And Cutting Center Machine

Model No.: HH-LJZ4-CNC-500×6000

Brand:HH

Place of Origin: China,Shandong

Payment Type: LC, T/T

Incoterm: FOB, CFR, CIF, EXW

Min Order: 1 Set/Sets

Port: Qingdao, Shanghai, Tianjin

CNC Aluminum Profile Drilling and Cutting Center Machine: Precision Engineering for Enhanced Performance

The CNC Aluminum Profile Drilling and Cutting Center Machine is a state-of-the-art solution for the precise drilling, cutting, and shaping of aluminum profiles. These machines are essential in industries where aluminum components are integral to production, such as in construction, automotive, and aerospace manufacturing. By utilizing CNC (Computer Numerical Control) technology, this machine offers unparalleled precision, repeatability, and efficiency, making it a preferred choice for manufacturers seeking high-quality aluminum products.

What is a CNC Aluminum Profile Drilling and Cutting Center Machine?

A CNC Aluminum Profile Drilling and Cutting Center Machine is a sophisticated piece of machinery designed to perform both drilling and cutting operations on aluminum profiles. This machine integrates drilling, milling, and cutting capabilities into a single unit, allowing for a wide range of operations on aluminum materials. With a user-friendly CNC interface, operators can program and control the machine to perform complex tasks with high precision.

The main function of the machine is to drill holes, cut profiles, and shape aluminum profiles according to specific dimensions and designs. This versatility makes it indispensable for industries that require high precision and efficiency in their aluminum fabrication processes.

Key Features of CNC Aluminum Profile Drilling and Cutting Center Machine

High Precision and Accuracy: The CNC Aluminum Profile Drilling and Cutting Center Machine is known for its exceptional precision. With the advanced CNC control system, the machine can execute precise drilling and cutting operations to micron-level accuracy, ensuring that all components meet stringent design specifications and tolerances.

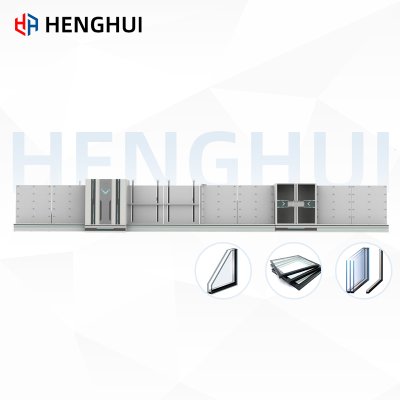

Multi-functional Capabilities: Unlike traditional machines that may specialize in a single operation, this machine offers a wide range of functions, including drilling, cutting, milling, and even tapping. This multi-functionality allows manufacturers to process a variety of aluminum profiles in one seamless workflow.

CNC Control System: The CNC system ensures that all operations are automated, reducing the need for manual labor and improving consistency in production. The control system allows for easy programming and customization of operations, meaning that complex designs can be executed with minimal effort. Users can adjust parameters and settings based on the specific requirements of each project.

Automated Material Handling: Many CNC Aluminum Profile Drilling and Cutting Center Machines are equipped with automated material handling systems. These systems facilitate the loading, unloading, and transfer of aluminum profiles, optimizing production efficiency and reducing the risk of human error.

High-Speed Cutting and Drilling: These machines are designed for high-speed operations, ensuring that production rates are optimized without compromising on precision. The fast processing speeds allow manufacturers to meet high demand and tight deadlines while maintaining excellent quality.

Durability and Reliability: Built with durable materials and high-quality components, CNC Aluminum Profile Drilling and Cutting Center Machines are designed for long-lasting performance. Their robust construction ensures that they can handle the demands of continuous operation, making them ideal for high-volume manufacturing environments.

User-Friendly Interface: The machine is equipped with an intuitive CNC interface, making it easier for operators to program and monitor the machine’s performance. The interface allows for quick adjustments and real-time tracking of production, which enhances overall operational efficiency.

Applications of CNC Aluminum Profile Drilling and Cutting Center Machine

Construction Industry: Aluminum profiles are widely used in the construction of window frames, doors, curtain walls, and other architectural components. The CNC Aluminum Profile Drilling and Cutting Center Machine provides the precision needed to cut and drill these profiles to the exact dimensions required for each project.

Automotive Manufacturing: In the automotive industry, aluminum is commonly used for car bodies, frames, and structural components. The CNC machine ensures that these parts are fabricated with high accuracy, providing a reliable and efficient solution for mass production of automotive parts.

Aerospace Industry: Aerospace applications require high-strength aluminum profiles for aircraft parts and structures. The CNC Aluminum Profile Drilling and Cutting Center Machine offers the precision and reliability needed to produce complex aluminum components that meet the strict safety and performance standards of the aerospace industry.

Furniture and Home Appliance Manufacturing: Aluminum profiles are also used in the production of furniture and home appliances. The ability to cut, mill, and drill aluminum with high accuracy makes the CNC Aluminum Profile Drilling and Cutting Center Machine an essential tool in the manufacturing process for these industries.

Electronics Industry: The electronics industry utilizes aluminum for components such as heat sinks, enclosures, and frames. The CNC Aluminum Profile Drilling and Cutting Center Machine ensures that these components are fabricated with precision to meet the specifications required for high-performance electronic devices.

Benefits of Using CNC Aluminum Profile Drilling and Cutting Center Machine

Enhanced Productivity: The automation and multi-functionality of the CNC Aluminum Profile Drilling and Cutting Center Machine significantly improve production efficiency. With the ability to perform multiple operations in one machine, manufacturers can reduce production time and costs while improving throughput.

Consistency and Quality: CNC machines eliminate the variability that can arise from manual operations, ensuring that every part produced is consistent and of high quality. This consistency is particularly important in industries where even small variations can impact product performance.

Customization and Flexibility: The CNC system allows for easy programming and adjustments to accommodate a wide range of aluminum profile designs. Manufacturers can customize the machine's settings for different products, enabling the production of highly detailed and complex profiles.

Reduced Waste and Errors: The precision of CNC machines minimizes material waste, as parts are fabricated to exact dimensions. Additionally, automated processes reduce the chances of human error, ensuring that products meet quality standards without the need for extensive rework.

Cost Efficiency: Although the initial investment in a CNC Aluminum Profile Drilling and Cutting Center Machine may be high, the long-term benefits of increased efficiency, reduced labor costs, and improved quality can result in significant cost savings over time.

Conclusion

The CNC Aluminum Profile Drilling and Cutting Center Machine is an essential tool for modern manufacturing, offering precision, efficiency, and versatility in the production of aluminum components. With its advanced CNC control system, multi-functional capabilities, and high-speed operations, this machine is ideal for industries ranging from construction to aerospace, automotive, and electronics. By enhancing productivity, ensuring consistency, and offering customization, the CNC Aluminum Profile Drilling and Cutting Center Machine is a game-changer for manufacturers looking to produce high-quality aluminum profiles with exceptional accuracy.