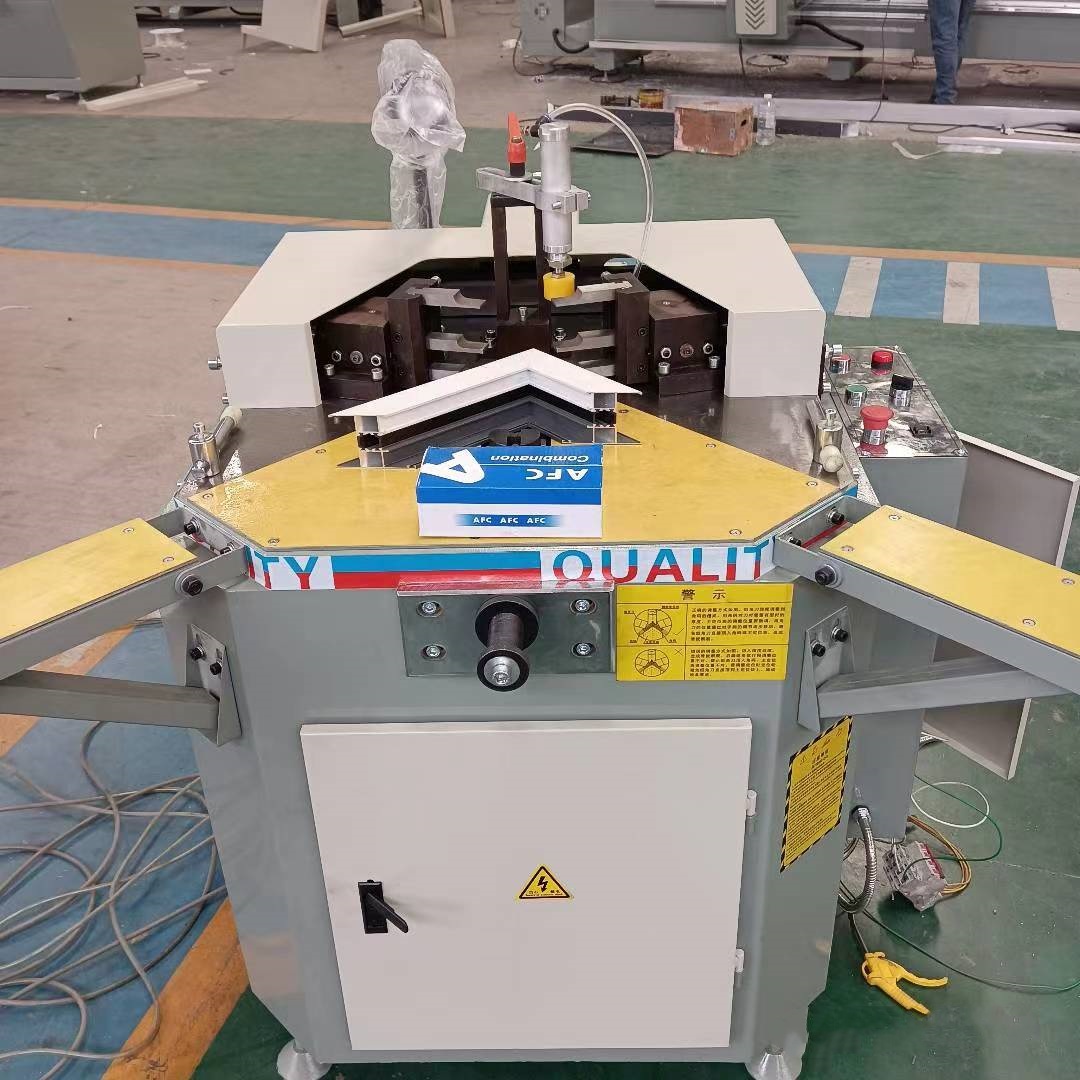

Heavy Single Head Corner Crimping Machine Aluminum Window

Model No.: LMB-120A

Brand: HH

Place of Origin:China

Dimension Size: 1.0×1.1×1.3m

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

Heavy Single Head Corner Crimping Machine for Aluminum Window: Precision and Strength for Window Frame Production

In the competitive world of aluminum window manufacturing, producing high-quality, durable, and secure corner joints is critical to ensuring the longevity and performance of the final product. The heavy single head corner crimping machine for aluminum window is a powerful and efficient tool designed to meet these needs. This machine is specifically engineered to provide accurate, strong, and consistent corner crimping for aluminum window frames, ensuring a perfect fit for both residential and commercial applications.

What Is a Heavy Single Head Corner Crimping Machine for Aluminum Window?

A heavy single head corner crimping machine for aluminum window is a specialized tool used to crimp the corners of aluminum window frames with precision and strength. The machine works by applying force to the aluminum profiles at the corners, creating a secure, long-lasting joint that enhances the durability of the frame. Unlike other crimping machines, the single head design allows for focused, powerful crimping on a single axis, providing superior control and accuracy.

This machine is particularly suitable for high-volume window production and is essential for manufacturers who need to produce aluminum window frames with consistent quality and strength. Its heavy-duty construction ensures that it can handle large or thick profiles, making it ideal for a wide range of aluminum window designs.

Key Features of the Heavy Single Head Corner Crimping Machine for Aluminum Window

Powerful Crimping Force

The heavy single head corner crimping machine uses a robust hydraulic or mechanical system to apply high pressure at the corners of aluminum profiles. This powerful crimping force ensures tight, secure joints that enhance the overall strength and stability of the window frame.Precision Control for Consistent Results

Equipped with advanced control systems, this machine ensures that each crimp is applied with high precision. The accurate control mechanisms guarantee that every frame is crimped to the exact specifications, ensuring uniformity across all production runs.Single Head Design for Focused Crimping

The single head design of this crimping machine allows for precise application of pressure to the corners of aluminum window frames. This focused crimping reduces the risk of misalignment or damage to the profile, ensuring high-quality joints every time.Adaptability for Various Profile Sizes

The heavy single head corner crimping machine is highly versatile, capable of handling a variety of aluminum profile sizes and thicknesses. This adaptability makes it suitable for manufacturing a wide range of aluminum window styles, from standard models to custom designs.Durable and Long-Lasting Construction

Built with durability in mind, this machine is made from high-quality materials that can withstand continuous operation in high-demand environments. Its heavy-duty construction reduces the need for frequent maintenance, ensuring that manufacturers can rely on it for long-term production.Automated Crimping Process for Efficiency

The automated crimping cycle of the heavy single head corner crimping machine improves operational efficiency. By reducing the need for manual intervention, this feature speeds up production times and minimizes human error, ensuring consistent quality in every batch.

Applications of the Heavy Single Head Corner Crimping Machine for Aluminum Window

The heavy single head corner crimping machine for aluminum window is ideal for use in various industries and applications, including:

Aluminum Window Manufacturing: Used extensively in the production of aluminum window frames, this machine ensures that the corners of the frames are securely crimped, providing enhanced strength and durability.

Construction and Building Projects: Crucial for the fabrication of aluminum window frames used in residential, commercial, and industrial buildings, the machine ensures the high-quality production of windows that can withstand environmental stress.

Custom Aluminum Window Production: Perfect for manufacturers who produce custom window designs, as it can handle a range of aluminum profiles and sizes, allowing for a flexible approach to window manufacturing.

Architectural and Facade Systems: The machine is also essential in producing windows for architectural applications, including curtain walls and facades, where precise and secure corner joints are required for both functionality and aesthetics.

Benefits of Using the Heavy Single Head Corner Crimping Machine for Aluminum Window

Increased Strength and Durability

The heavy crimping force applied by the single head crimping machine ensures that the corners of aluminum window frames are securely joined, improving the overall strength and longevity of the frames. This results in windows that can withstand external forces such as wind, rain, and wear over time.Enhanced Efficiency and Productivity

The automated crimping cycle, combined with its single head design, allows for faster production times, significantly improving productivity. With fewer manual steps and reduced chances of error, the machine streamlines the manufacturing process.Consistent Quality Across Production Runs

The precision control systems and powerful crimping force ensure that every window frame is made with consistent quality, meeting the required specifications for strength and durability. This consistency is crucial for maintaining high product standards and customer satisfaction.Cost-Effective Manufacturing

By automating the crimping process and reducing the need for manual intervention, the heavy single head corner crimping machine for aluminum window helps reduce labor costs while increasing output. Its long-lasting construction also minimizes downtime and maintenance costs, making it a cost-effective choice for manufacturers.Versatility for Various Designs

The machine’s adaptability to different profile sizes and thicknesses means it can be used to produce a wide range of aluminum window styles, including custom and non-standard designs. This versatility enhances the manufacturer’s ability to meet diverse customer demands.

Why Choose the Heavy Single Head Corner Crimping Machine for Aluminum Window?

The heavy single head corner crimping machine for aluminum window is an essential tool for any manufacturer aiming to produce high-quality, durable aluminum window frames. With its precision, efficiency, and powerful crimping capabilities, it ensures that each frame is securely joined, providing both structural integrity and aesthetic appeal. Whether for mass production or custom orders, this machine will enhance the efficiency, quality, and competitiveness of your aluminum window manufacturing process.

Conclusion

The heavy single head corner crimping machine for aluminum window is an invaluable asset in the production of aluminum window frames. Offering powerful crimping force, precision control, and efficient automated operation, this machine ensures that your window frames are strong, durable, and of the highest quality. By investing in this advanced crimping technology, manufacturers can meet the growing demand for high-performance aluminum windows while improving their overall production efficiency.