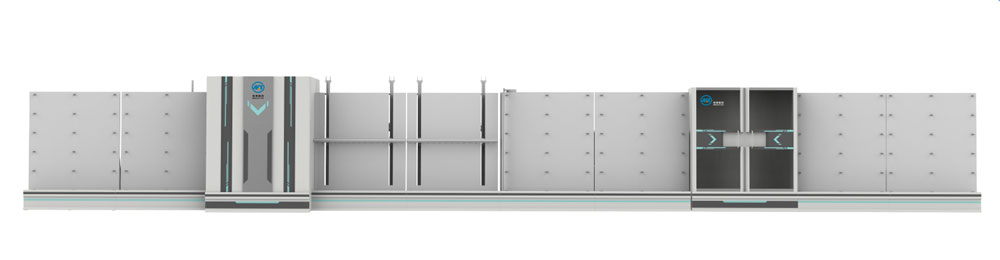

Automatic Gas Filling Insulating Glass Machine Production Line

Model No.: HH-CQX-2535

Brand: HH

Place of Origin:China

Glass Thickness: ≤50 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

In the modern glass manufacturing industry, efficiency, precision, and quality are paramount. The Automatic Gas Filling Insulating Glass Machine Production Line has emerged as a game-changer, transforming how insulating glass units (IGUs) are produced. This advanced production line integrates automated gas filling technology, ensuring superior insulation performance and energy efficiency for windows and facades worldwide.

What is an Automatic Gas Filling Insulating Glass Machine Production Line?

An Automatic Gas Filling Insulating Glass Machine Production Line is a fully automated system designed to manufacture insulating glass panels by filling the space between glass layers with inert gas, such as argon or krypton. This gas filling improves the thermal insulation properties of glass, reducing heat transfer and enhancing energy savings in buildings.

This production line typically combines several key components: glass washing, spacer filling, gas filling, sealing, and final inspection—all synchronized for optimal productivity and minimal human intervention.

Key Advantages of Using an Automatic Gas Filling Insulating Glass Machine Production Line

Enhanced Energy Efficiency

Filling insulating glass with inert gas significantly improves thermal insulation. The automatic gas filling insulating glass machine production line ensures consistent, accurate gas injection, minimizing heat loss and contributing to sustainable building designs.High Production Efficiency

Automation reduces manual labor and accelerates production speed. The automatic gas filling insulating glass machine production line can handle high-volume orders while maintaining precise quality control, essential for meeting market demands.Improved Quality and Consistency

Automated processes eliminate human error, ensuring that every insulating glass unit has the correct gas concentration and perfect sealing. This reliability is critical for long-term durability and performance.Cost-Effective Operation

While initial investment is higher, the automatic gas filling insulating glass machine production line reduces waste, labor costs, and rework expenses. Over time, this leads to significant cost savings and higher ROI.

Core Components of the Production Line

Glass Washing Unit: Prepares glass surfaces for optimal sealing and gas filling.

Spacer Filling Machine: Inserts desiccants and sets the spacer between glass panes.

Automatic Gas Filling Machine: Injects inert gas into the sealed cavity at precise concentrations.

Sealing Machine: Applies durable sealant to lock gas inside and protect against moisture.

Inspection System: Checks the final product for leaks, uniform gas distribution, and structural integrity.

Applications of the Automatic Gas Filling Insulating Glass Machine Production Line

This advanced production line is essential in manufacturing insulated glass for:

Residential and commercial windows

Curtain walls and facades

Automotive glass

Solar panels

Its versatility and precision make it a preferred choice for glass manufacturers aiming for high-quality, energy-efficient products.

Why Choose an Automatic Gas Filling Insulating Glass Machine Production Line?

Investing in an automatic gas filling insulating glass machine production line means embracing cutting-edge technology that guarantees quality, speed, and sustainability. Manufacturers can meet stringent environmental standards while increasing market competitiveness through superior product performance.

Conclusion

The Automatic Gas Filling Insulating Glass Machine Production Line is revolutionizing insulating glass manufacturing by combining automation with precision gas filling technology. This innovation not only enhances energy efficiency and product quality but also optimizes production processes and reduces costs.

For glass manufacturers seeking to lead in the green building revolution, adopting an automatic gas filling insulating glass machine production line is the smart, future-proof choice.

Product advantages

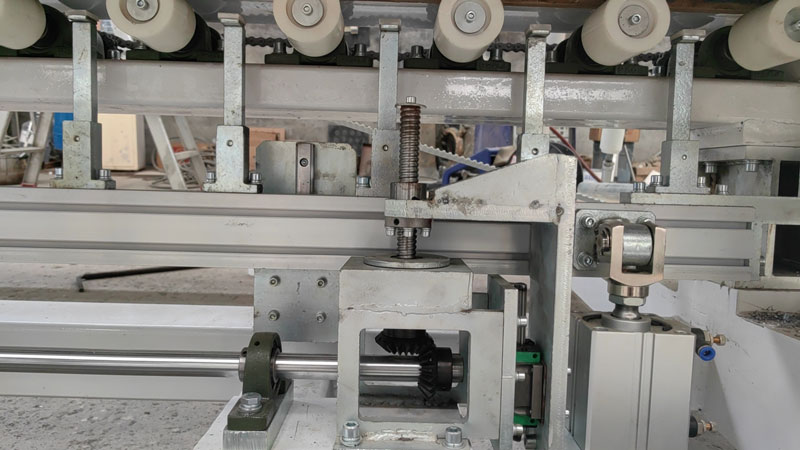

(1) Comprehensive functionality with programs for both outside and inside assembly.

(2) Automated CNC Insulating Glass Production Line with automatic LOW-E identification.

(3) Controlled by Siemens PLC with a touch-sensitive screen for user interface.

(4) Utilizes imported vacuum generators and suction cups for optimal glass suction.

(5) Customizes production for step IG units and triple glass based on customer specifications.

(6) Fully automatic variable frequency speed adjustment across all distances, reducing idle time and enhancing production efficiency.

Product parameters are as follows

Model | HH-CQX-2535 |

Power Supply | 380V 50Hz 42KW |

Air Pressure | 0.6~0.8Mpa |

Max. Glass Size | 2500×3500mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Conveying Speed | 0~50m/min |

Cleaning Speed | 2~12m/min |

Overall Dimension | 28500×2000×3600mm |