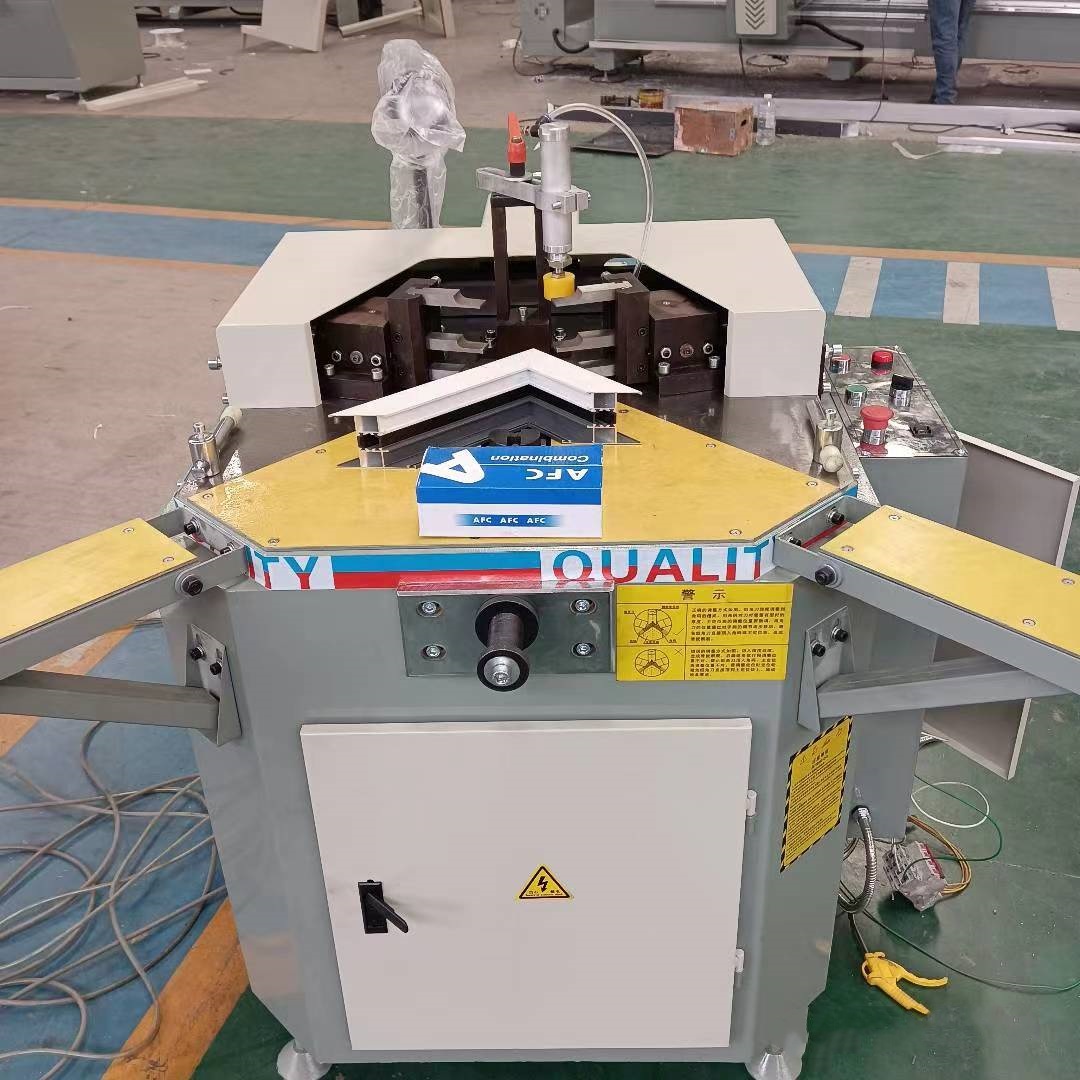

Aluminum Window Corner Crimping Machine

Model No.: LMB-120

Brand: HH

Place of Origin:China

Dimension Size: 0.9×1.0×1.3m

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

Aluminum Window Corner Crimping Machine: Essential Tool for High-Quality Aluminum Window Manufacturing

When it comes to producing durable and secure aluminum window frames, precision is key. The aluminum window corner crimping machine plays a crucial role in ensuring that the corners of the frames are joined with maximum strength and accuracy. This essential tool is designed to crimp the corners of aluminum profiles securely, creating tight, durable joints that enhance the overall structural integrity of the window frame. Whether you're working with standard profiles or custom designs, the aluminum window corner crimping machine provides the precision and efficiency needed for high-quality production.

What Is an Aluminum Window Corner Crimping Machine?

An aluminum window corner crimping machine is a specialized tool used to join the corners of aluminum window frames by applying pressure to crimp the profile into place. This process ensures that the corners are securely joined, preventing separation or distortion over time. The machine is engineered to handle both small and large aluminum profiles, making it suitable for various window types, from residential to commercial applications.

The aluminum window corner crimping machine is crucial for high-volume production environments where consistency and strength are a priority. It allows manufacturers to produce windows that not only meet structural standards but also provide an aesthetically pleasing appearance.

Key Features of the Aluminum Window Corner Crimping Machine

High Precision Crimping Force

The aluminum window corner crimping machine delivers consistent crimping force, ensuring that the aluminum profiles are securely joined at the corners. This high precision reduces the risk of misalignment or weak joints, guaranteeing a long-lasting product.Advanced Control Systems

Equipped with modern control systems, this machine allows for fine-tuned adjustments in crimping pressure, angle, and force. Operators can set precise parameters, ensuring that the crimping process is carried out with the utmost accuracy and consistency.Durable and Sturdy Build

The machine is designed to withstand continuous use in demanding production environments. Made with high-quality materials, the aluminum window corner crimping machine is built to last, providing years of reliable performance while minimizing maintenance needs.Versatile Profile Compatibility

One of the standout features of the aluminum window corner crimping machine is its ability to handle a wide range of aluminum profiles. Whether you're working with standard or custom profiles, this machine can be easily adjusted to accommodate different sizes and thicknesses.Automatic Crimping Cycle

The automatic crimping cycle improves the overall production process by reducing the need for manual intervention. This automation speeds up the crimping process and minimizes human error, ensuring that each aluminum frame is crimped to perfection with every cycle.Compact and Space-Efficient Design

Despite its heavy-duty capabilities, the aluminum window corner crimping machine is designed with a compact footprint. This makes it ideal for manufacturing environments where space is limited, allowing manufacturers to maximize floor space without sacrificing performance.

Applications of the Aluminum Window Corner Crimping Machine

The aluminum window corner crimping machine is used in a variety of industries and applications, including:

Aluminum Window Manufacturing: The primary use of this machine is in the production of aluminum windows, where it ensures that the corners are tightly crimped, contributing to the overall strength and durability of the window frame.

Aluminum Door Fabrication: In addition to windows, this machine is also used for fabricating aluminum doors, which require strong and secure corner joints for proper function.

Architectural Systems and Facades: The aluminum window corner crimping machine is also vital in the production of aluminum curtain walls and facades, where precise corner joints are essential for both structural stability and aesthetics.

Custom Aluminum Fabrication: For manufacturers who specialize in custom aluminum window and door designs, this machine provides the flexibility to handle various profile sizes and shapes, ensuring that every custom order meets the necessary specifications.

Benefits of Using the Aluminum Window Corner Crimping Machine

Enhanced Durability and Strength

The aluminum window corner crimping machine ensures that each corner joint is securely crimped, significantly increasing the overall strength of the window frame. This durability is crucial for windows that need to withstand external forces, such as wind, weather, and wear.Improved Production Efficiency

With its automatic crimping cycle and high precision, the aluminum window corner crimping machine helps speed up the manufacturing process. By reducing the time spent on manual crimping, manufacturers can increase their output and improve overall efficiency.Consistent Quality Control

The advanced control systems in the aluminum window corner crimping machine ensure that every crimping operation is performed with the same level of precision, leading to uniform, high-quality joints across all frames. This consistency is essential for maintaining product quality and meeting industry standards.Reduced Labor Costs

The automation of the crimping cycle reduces the need for manual labor, thereby lowering labor costs. By streamlining the production process, the machine also reduces the likelihood of human error, leading to fewer defects and waste.Versatility for Various Aluminum Profiles

Whether you're working with standard aluminum profiles or custom-designed ones, the aluminum window corner crimping machine is adaptable and can handle a wide range of sizes and thicknesses. This versatility ensures that manufacturers can meet the needs of a diverse customer base.Long-Term Reliability and Low Maintenance

Built with durable materials and designed for heavy-duty use, the aluminum window corner crimping machine is a reliable investment for manufacturers. Its sturdy construction minimizes the need for frequent maintenance, ensuring that it continues to perform efficiently for many years.

Why Choose the Aluminum Window Corner Crimping Machine?

Choosing the aluminum window corner crimping machine means investing in a tool that enhances production quality, efficiency, and consistency. With its advanced features, powerful crimping capability, and versatility, this machine is an invaluable asset for any manufacturer of aluminum windows and doors. By producing tightly crimped, secure corner joints, it ensures that your aluminum frames are strong, durable, and of the highest quality.

Conclusion

The aluminum window corner crimping machine is a vital tool in the aluminum window manufacturing process. Its precision, efficiency, and versatility make it an essential asset for any manufacturer looking to produce high-quality aluminum frames. With the ability to handle a wide range of aluminum profiles and deliver consistent, secure crimping, this machine helps ensure that every frame is strong, durable, and built to last. Whether you're producing standard windows or custom designs, the aluminum window corner crimping machine is the key to achieving exceptional results in your production line.