Automatic Angle Code Cutting Saw with High Production Efficiency

Model No.: LJJ-450

Brand:HH

Place of Origin: China,Shandong

Payment Type: LC, T/T

Incoterm: FOB, CFR, CIF, EXW

Min Order: 1 Set/Sets

Port: Qingdao, Shanghai, Tianjin

In today’s fast-paced window and door manufacturing landscape, speed and precision define success. If you're still relying on semi-automated or manual tools to cut aluminum angle codes, you're limiting your productivity and profits. The solution? An Automatic Angle Code Cutting Saw with High Production Efficiency—a smart investment that empowers your factory with high-speed, precision cutting and minimal labor cost.

What Is an Automatic Angle Code Cutting Saw with High Production Efficiency?

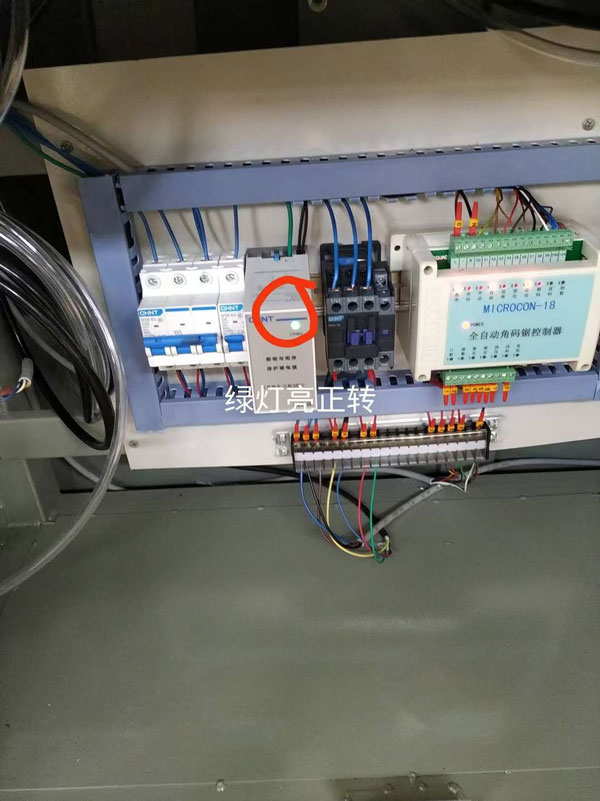

An Automatic Angle Code Cutting Saw with High Production Efficiency is a high-precision CNC-controlled machine designed specifically for cutting aluminum angle codes—also known as corner connectors—for window and door frames. These machines automate the cutting process, delivering clean, accurate results at a significantly faster rate than traditional equipment.

Whether you're cutting hundreds or thousands of angle codes daily, this machine helps you stay ahead of production targets while improving overall quality.

Why Your Factory Needs an Automatic Angle Code Cutting Saw with High Production Efficiency

✅ High-Speed Output for Maximum ROI

The core advantage of an Automatic Angle Code Cutting Saw with High Production Efficiency is exactly what the name implies—production speed. With optimized cutting cycles, intelligent blade positioning, and automated clamping systems, this saw can process more angle codes in one shift than manual saws can handle in a full day.

✅ Perfectly Accurate, Every Time

In aluminum frame assembly, accuracy isn’t optional—it’s essential. Misaligned angle codes lead to frame failure, gaps, and costly remakes. This CNC-driven saw guarantees cutting precision down to 0.1 mm, ensuring every angle code fits seamlessly.

✅ Save Labor, Cut Costs

Automation means fewer workers are needed to achieve more. A single operator can control the entire cutting process, reducing manpower costs and eliminating fatigue-related errors.

✅ Enhanced Material Utilization

Advanced programming ensures optimal cutting paths, reducing material waste. That’s higher yield per aluminum bar—and thousands of dollars saved annually.

Core Features of a High-Performance Automatic Angle Code Cutting Saw

When shopping for an Automatic Angle Code Cutting Saw with High Production Efficiency, look for these must-have features:

Touchscreen CNC control with multi-language interface

Servo-driven dual blade cutting system

Precision linear guide rails for smooth, accurate motion

Automatic feeding and clamping for hands-free operation

Burr-free cutting edges with minimal post-processing required

Dust extraction and scrap collection systems for clean working environment

Real-World Impact: What Manufacturers Are Saying

A top-tier aluminum window and curtain wall fabricator in South Korea upgraded to an Automatic Angle Code Cutting Saw with High Production Efficiency and saw a 60% increase in daily output. Their rejection rate also dropped by 30%, improving customer satisfaction and cutting production costs.

Another customer in the Middle East reported cutting labor costs in half after implementing this fully automated system into their production line.

How to Select the Right Machine for Your Operation

Not all machines are created equal. When evaluating options for an Automatic Angle Code Cutting Saw with High Production Efficiency, consider:

✅ Can it handle the volume you need daily or hourly?

✅ Does it support different profile types and connector shapes?

✅ Are the materials and components built for 24/7 industrial use?

✅ Is after-sales support available for training, maintenance, and repairs?

Working with a trusted supplier ensures your investment delivers lasting value and long-term performance.

Upgrade Now—Stay Ahead of the Competition

The aluminum window and door market is evolving. Customers expect fast delivery, high strength, and seamless finishes. By equipping your production line with an Automatic Angle Code Cutting Saw with High Production Efficiency, you’ll:

Increase daily output

Improve product quality

Reduce manual errors

Lower operational costs

Gain a decisive edge over competitors

Ready to Scale Your Manufacturing with Speed and Precision?

Don’t let outdated tools slow you down. Discover how an Automatic Angle Code Cutting Saw with High Production Efficiency can revolutionize your production workflow.

Contact our technical sales team today for personalized guidance, quotes, and machine specifications tailored to your exact production needs.