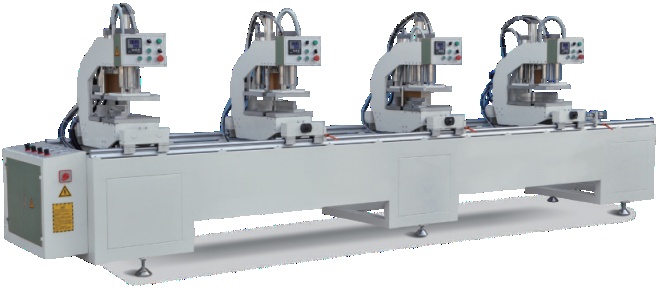

Four-head Seamless Welding Machine for Aluminum Door

Model No.: SHZ4-4500×100B

Brand: HH

Place of Origin:China

Welding range: 400-4300mm

Dimension Size:5300×1000×1700mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

When craftsmanship meets cutting-edge automation, the result is the Four-head Seamless Welding Machine for Aluminum Door—an essential investment for modern aluminum fabrication workshops aiming for zero-defect joints, higher production efficiency, and premium-quality aluminum doors.

This next-gen machine is engineered for simultaneous multi-angle welding of aluminum door frames with seamless joints, delivering both speed and flawless finish—crucial in today’s competitive construction and fenestration industries.

What Is a Four-head Seamless Welding Machine for Aluminum Door?

A Four-head Seamless Welding Machine for Aluminum Door is a fully automatic, CNC-controlled system that allows simultaneous welding of four corners of an aluminum frame. Unlike traditional welding setups, this machine ensures seamless joints—completely free from visible weld lines—ideal for modern high-end aluminum door products.

Whether you're manufacturing swing doors, sliding systems, or architectural aluminum profiles, this machine guarantees strength, accuracy, and visual excellence in every weld.

Top Features of the Four-head Seamless Welding Machine for Aluminum Door

✅ 1. Fully Automatic Four-head Welding

All four corners of the aluminum door frame are welded in a single cycle, significantly reducing cycle time and improving alignment accuracy. This results in higher daily output and reduced labor dependency.

? "Before this machine, we had to weld and align each corner manually. Now? 4 corners done in under 2 minutes!"

— @EliteFrameWorks

✅ 2. True Seamless Finish – No Polishing Needed

Thanks to its seamless corner welding system, the machine uses precision pressure control and synchronized heating to eliminate welding scars. Your aluminum doors leave the workshop looking like they’re made from a single piece—no secondary processing needed.

? “We stopped polishing corners after switching to this model—our customers instantly noticed the clean finish.”

— @UrbanAluDesigns

✅ 3. Advanced Touchscreen PLC Control

Operators can manage the machine via an intuitive PLC touchscreen interface. Control heat, pressure, and timing for each head, store multiple welding recipes for different profiles, and monitor real-time performance—no advanced training needed.

✅ 4. Compatible with Multiple Aluminum Profiles

The machine accommodates a wide range of aluminum profiles (standard, thermal break, decorative) used in various door systems. Changeovers are simple and quick—perfect for custom and batch production alike.

✅ 5. Robust Build with Precision Rails

Equipped with high-precision guide rails, imported cylinders, and industrial-grade components, the machine runs smoothly even under continuous heavy-duty use. Built to last, with minimal downtime.

Technical Specifications (Sample Model)

| Feature | Specification |

|---|---|

| Max Welding Size | 4500mm x 3000mm |

| Welding Pressure | Adjustable (per head) |

| Control System | PLC Touchscreen |

| Power Supply | 380V / 50Hz / 3 Phase |

| Profile Types | Aluminum, Thermal Break, Wood-grain Aluminum |

| Welding Accuracy | ±0.2mm |

| Seam Finish | 100% Seamless (No post-polish) |

Common Applications

The Four-head Seamless Welding Machine for Aluminum Door is a versatile tool used in:

✅ Residential & commercial aluminum door manufacturing

✅ Curtain wall frame fabrication

✅ High-end villa & office partition systems

✅ Thermal break system door production

✅ Modern architectural aluminum projects

Simulated User Reviews

⭐️⭐️⭐️⭐️⭐️

“Precision and polish in one go”

"We doubled our welding capacity and cut post-processing time by 90%. This machine changed our business."

— @SkylineDoorsFactory

⭐️⭐️⭐️⭐️⭐️

“Solid, fast, easy to operate”

"Even our new operators learned the system in a day. Seamless welds look better than manual ones ever did."

— @AluProTech

⭐️⭐️⭐️⭐️

“Pays for itself fast”

"Yes, it’s an investment—but within three months, we saw ROI. Reduced errors, less waste, happier clients."

— @NextEdgeFrames

Why Invest in a Four-head Seamless Welding Machine for Aluminum Door?

Aluminum door trends are shifting toward minimalist, high-end finishes. Seamless welds are no longer a luxury—they’re a customer expectation. This machine not only delivers those flawless results but also:

✅ Speeds up production by 2–3X

✅ Minimizes labor training needs

✅ Improves product consistency

✅ Reduces polishing and finishing costs

✅ Raises your workshop’s reputation instantly