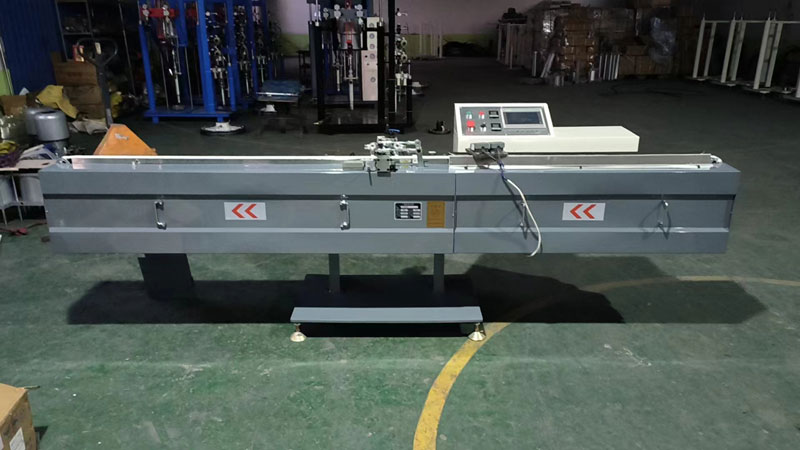

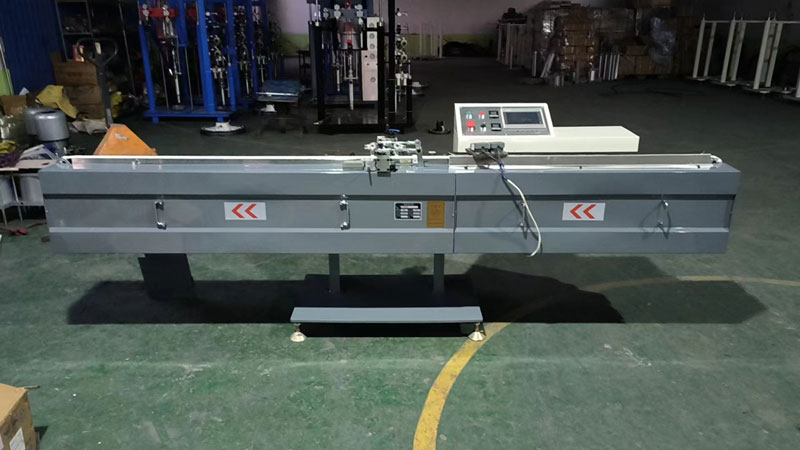

Automatic Butyl Sealant Coating Machine Glue Mixing System New Condition Glass Manufacturing Plant Industries Features Core Pump

Model No.: HH-DJJ-05

Brand: HH

Place of Origin:China

Working Speed: 2-45m/min

Payment Type:L/C,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

1.Introduction of products

HH-DJJ-05 butyl rubber extruder has the function of sealing rectangular and curved aluminum spacers. This machine is the first in the industry to use an advanced automatic glue adjustment system, which can be adjusted arbitrarily within the range of 6 to 18.5 mm. Our company's hot melt butyl rubber

extruder has 5 variable frequency adjustable processing speeds, and the maximum glue output speed can reach 45 meters/minute.

2.Product advantages

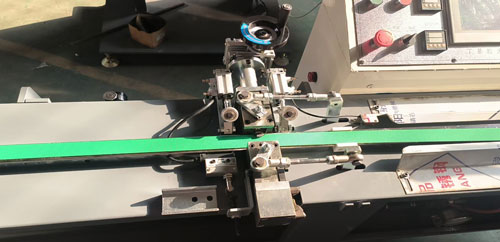

(1) Equipped with an advanced pneumatic pump system, the equipment pressure is more stable and more energy-efficient.

(2) The touch screen control system makes the operation clearer, simpler and easier.

(3) The conveying link adopts a variable frequency speed regulation system, and the speed can be selected from 1 to 5 gears,

ranging from 15 to 30 meters per minute.

(4) It is the first in the industry to adopt an advanced automatic dispensing system, which can be adjusted within the range of 6 to 18.5 mm.

(5) The melter adopts a rotary structure and can rotate freely, making gluing and maintenance more convenient.

(6) It has a large-size glue tank, and the glue filling amount can reach 14 kg at a time.

(7) The workbench can be raised and lowered, which is an optional function.

3.Product parameters are as follows

Model | HH-DJJ-05 |

Power Supply | 220V 50Hz 3.75KW |

Air Pressure | 0.5-0.8Mpa |

Air Consumption | 60 L/Min |

Adjustable Range | 6~18.5 mm |

Temperature | 110-140℃ |

Pistons Diameter | ∮200mm |

Working Speed | 2-45m/min |

Dispensing Pressure | 10-20Mpa |

Overall Dimension | 3000x650x1100mm |

4.Packaging and Transportation

5.FAQ