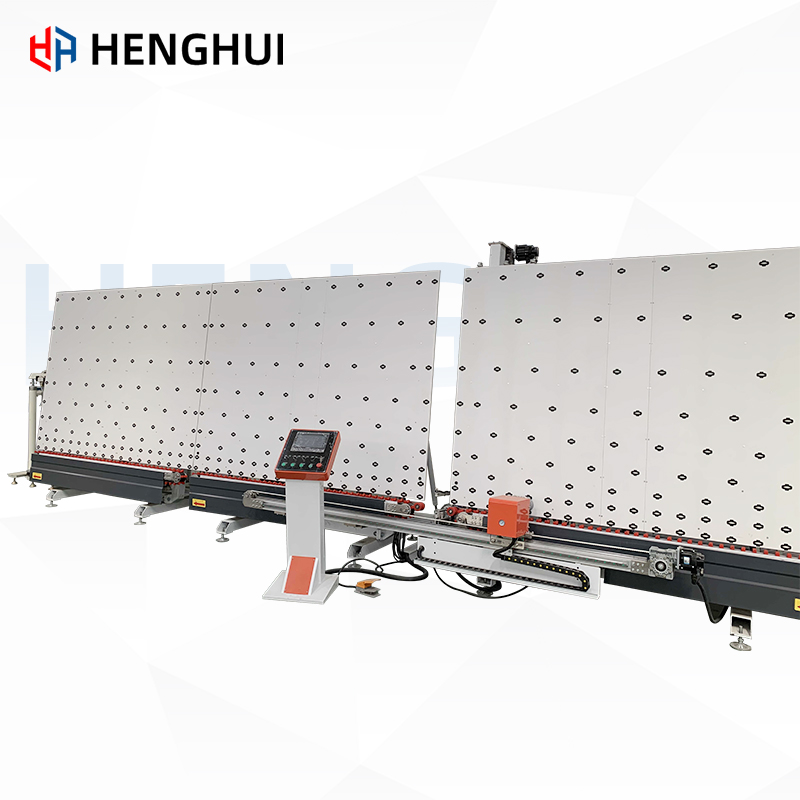

2500 Full Automatic Insulating Glass Sealing Robot

Model No.: HH-FJX-2500

Brand: HH

Place of Origin:China

Max Glass Size: 2500*4000 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

The 2500 Full Automatic Insulating Glass Sealing Robot is an advanced solution designed to automate the sealing process in insulating glass (IG) manufacturing. This cutting-edge robot significantly enhances production speed, precision, and product quality by delivering consistent and airtight sealing on insulating glass units. As the demand for high-quality energy-efficient glass grows, the 2500 Full Automatic Insulating Glass Sealing Robot has become essential for modern glass factories aiming to optimize their manufacturing lines.

This article explores the features, benefits, and applications of the 2500 Full Automatic Insulating Glass Sealing Robot, helping manufacturers improve their insulating glass production capabilities.

What Is the 2500 Full Automatic Insulating Glass Sealing Robot?

The 2500 Full Automatic Insulating Glass Sealing Robot is a highly automated machine designed specifically for the sealing of insulating glass units with superior accuracy. It applies sealant uniformly around the glass edges, ensuring airtightness and durability that enhance thermal insulation and weather resistance.

This robot supports large glass sizes up to 2500mm, catering to the needs of various IG production scales with minimal manual intervention.

Key Features of the 2500 Full Automatic Insulating Glass Sealing Robot

High Precision Sealing: Ensures consistent sealant application with tight tolerances to prevent leaks.

Full Automation: Reduces labor costs by automating the entire sealing process from start to finish.

Large Size Capacity: Handles insulating glass units up to 2500mm in width or length.

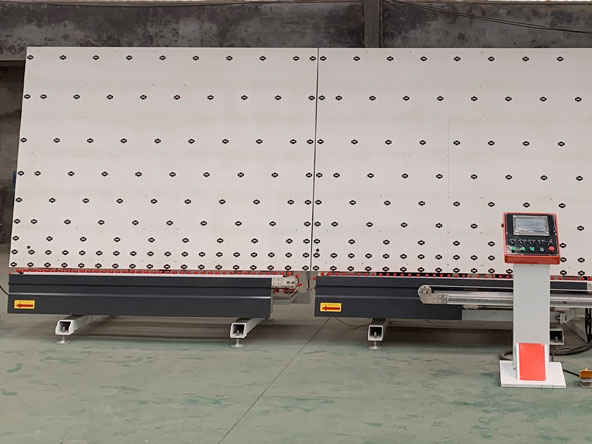

User-Friendly Interface: Equipped with touchscreen control for easy programming and monitoring.

Flexible Operation: Supports various sealant types and glass thicknesses.

Efficient Workflow Integration: Easily integrates into existing IG production lines.

Benefits of Using the 2500 Full Automatic Insulating Glass Sealing Robot

Improved Product Quality: Uniform sealing ensures long-lasting airtightness and durability.

Increased Production Efficiency: Faster sealing speeds reduce cycle times and boost throughput.

Labor Cost Reduction: Automation minimizes manual labor and related errors.

Consistent Operation: Reliable performance reduces material waste and rework.

Enhanced Safety: Automation reduces worker exposure to hazardous sealants.

Applications of the 2500 Full Automatic Insulating Glass Sealing Robot

Residential and Commercial IG Production: Suitable for sealing windows and doors of various sizes.

Architectural Glass Manufacturing: Ideal for curtain walls and high-performance insulating glass.

Automotive Glass Sealing: Adaptable for insulated glass used in vehicles.

Specialty IG Products: Supports customized sealing needs with various sealants.

How to Choose the Right Insulating Glass Sealing Robot?

Evaluate the maximum glass size compatibility (up to 2500mm for this model).

Consider automation level and ease of operation.

Check the robot’s adaptability to different sealant materials.

Ensure reliable technical support and maintenance services.

Prioritize energy efficiency and eco-friendly operation.

Conclusion

The 2500 Full Automatic Insulating Glass Sealing Robot is a game-changer for insulating glass manufacturers seeking higher quality, faster production, and cost savings. With its precision sealing and full automation capabilities, this robot empowers factories to meet growing market demands while maintaining superior product standards.

Product advantages

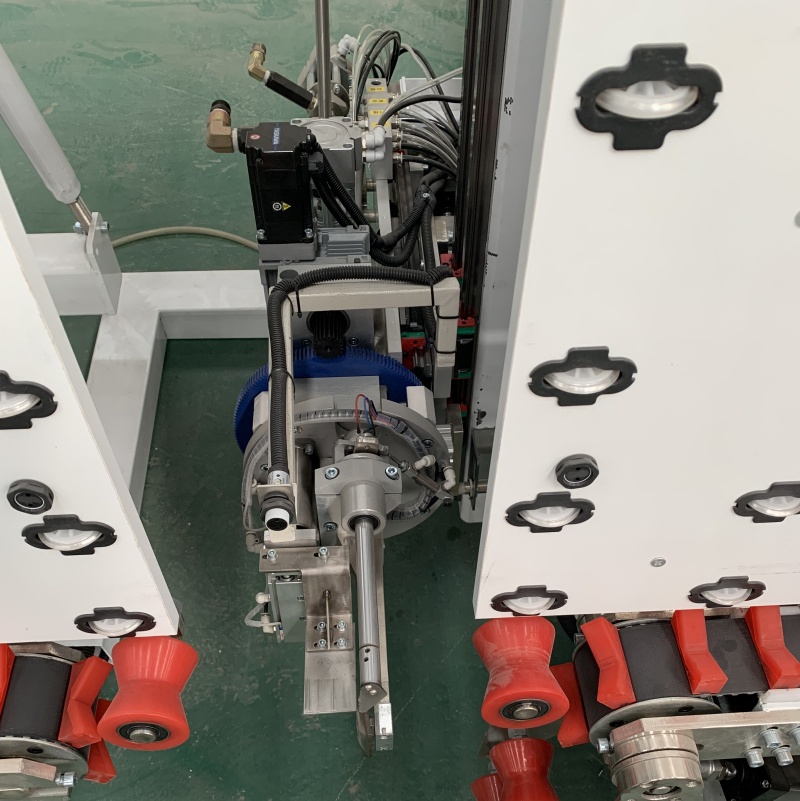

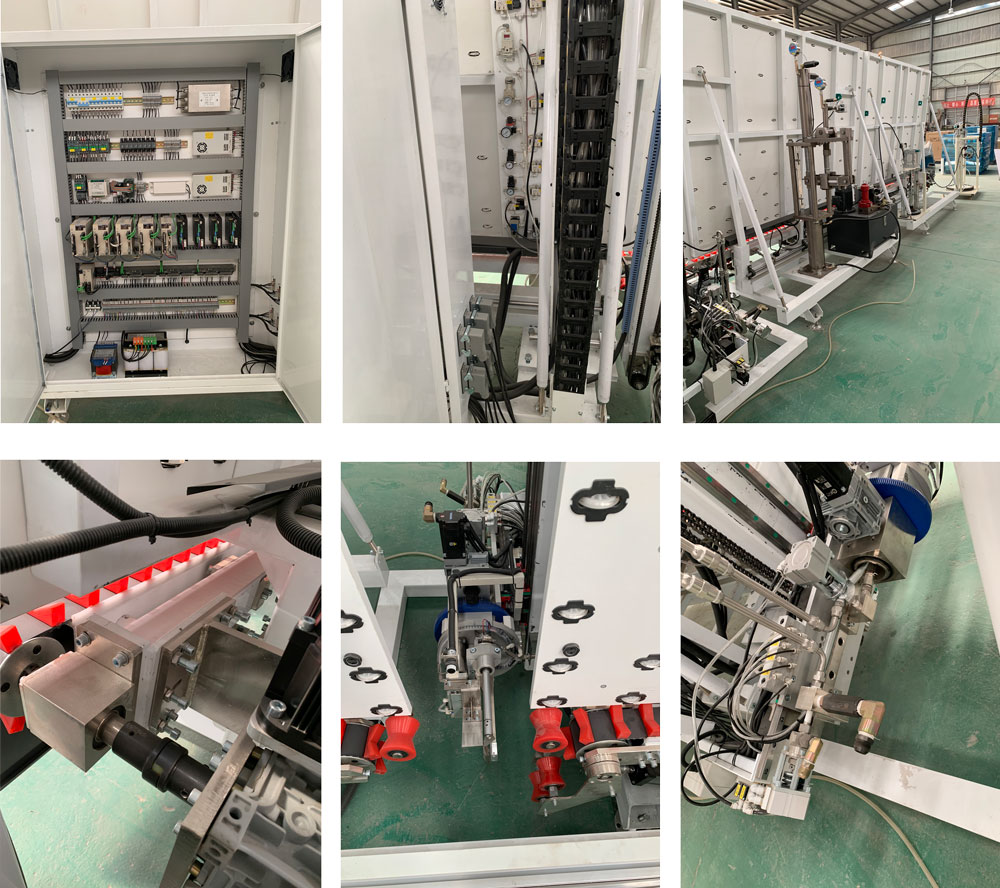

(1) The adhesive continuity of rectangular insulating glass of various sizes can be realized, with high adhesive efficiency and stable quality.

(2) Two completely independent glue supply systems, two kinds of sealants can be arbitrarily switched (optional).

(3) The glass can be pre-stored in the third paragraph to strengthen the continuity of equipment operation and improve production efficiency.

(4) The side coating is full without bubbles, and the corner is full without manual trimming.

(5) World-renowned brand Yaskawa motion control system and servo control system have stable performance.

(6) Accurate synchronous belt transmission system ensures smooth and pollution-free operation of glass.

(7) Using two sealant supply systems, switch fast and one-key operation. (Model II)

(8) Suitable for triple glazing.

Product parameters are as follows

Model | HH-FJX-2500x4000 |

Power Supply | 380V 50Hz 13KW |

Air Pressure | 0.5~0.7Mpa |

Max. Glass Size | 2500×4000mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~12mm |

Insulating Glass Thickness | ≤50mm |

Working Speed | 0~50m/min |

Max. Dispensing Pressure | ≤35Mpa |

Overall Dimension | 12000×2000×3550mm |